Nanocrystalline Soft Magnetic Material FINEMET®

Product Catalog Download

Click here to download the product catalog

Contact

Soft Magnetic Materials and Components (for FINEMET® Applied Product and Ribbon)

What is FINEMET® ?

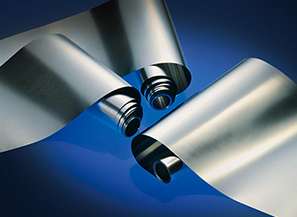

FINEMET® is crystalized alloy ribbon with main chemical composition of Fe.

This crystalized alloy have grains which are extremely uniform and small “about 10nm in size”.

FINEMET® is Proterial's original product realizes drastic improvement of magnetic characteristics.

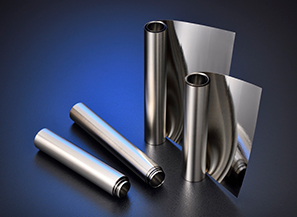

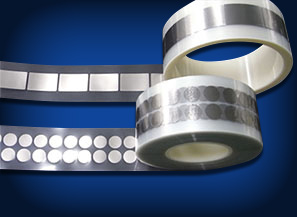

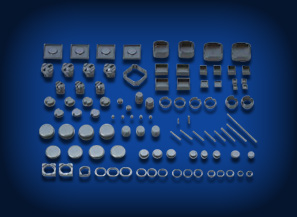

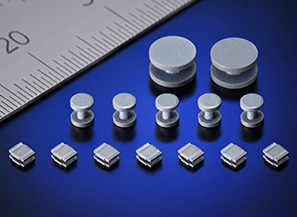

Various product groups

Features

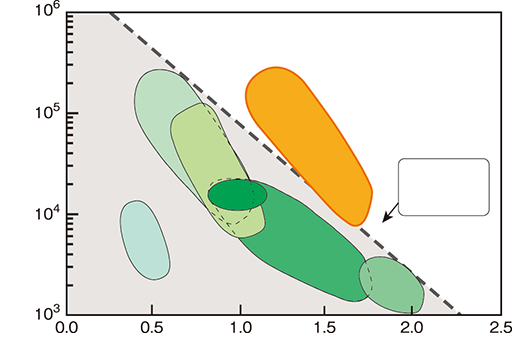

- 1Satisfy both high saturation magnetic flux density and high permeability (High permeability, High saturation flux density)

High saturation magnetic flux density comparable to Fe-based amorphous metal. High permeability comparable to Co-based amorphous metal.

- 2Low core loss (Low core loss)

1/5th the core loss of Fe based amorphous metal and approximately the same core loss as Co-based amorphous metal.

- 3Excellent temperature characteristics and small aging effects (Excellent temperature characteristics)

Small permeability variation (less than ±10%) at a temperature range of -50°C~150°C. Unlike Co-based amorphous metals, aging effects are very small.

- 4Low magnetostriction (Low magnetstriction)

Less affected by mechanical stress. Very low audio noise emission.

- 5Excellent characteristics over wide frequency range (High squareness)

High permeability and low core loss over wide frequency range, which is equivalent to Co-based amorphous metal.

- 6Flexibility to control magnetic properties“B-H curve shape”during annealing (High permeability)

Three types of B-H curve squareness, high, middle and low remanence ratio, corresponding to various applications.

Superior

High saturated flux density, high relative permeability and low core loss. Superior to conventional materials.

Relative permeability μr

Saturation flux density Bs(T)

FINEMET®

Co based amorphous

Permalloy

Fe-Al-Si

Mn-Zn ferrite

Fe based amorphous

Si-steel

The limit of the

conventional

special material

f=1 kHz

Features and Typical Applications of FINEMET®

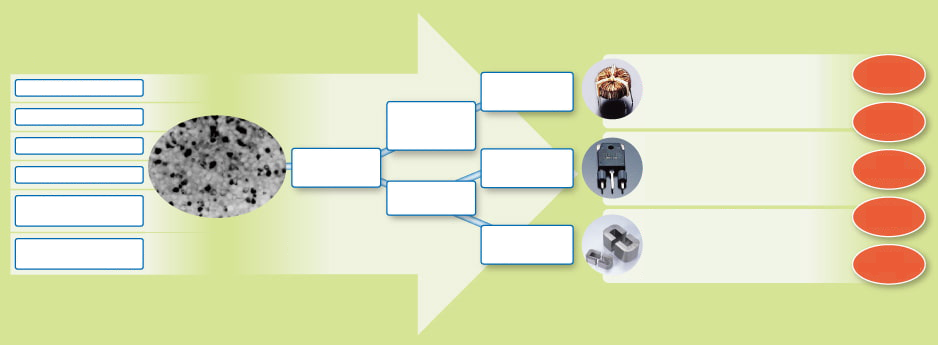

Proterial, Ltd. produces various types of soft magnetic materials, such as Permalloy, soft ferrite, amorphous metal, and FINEMET®, and we use these materials in our product's applications. We continually improve our material technology and develop new applications by taking advantage of the unique characteristics these materials provide. FINEMET® is a good example. It is our hope, FINEMET® will be the best solution for your application.

Technology

Rapid quenching

Nano structure control

Annealing

Measurement

Electromagnetic

circuit designing

Electromagnetic and

electro circuit designing

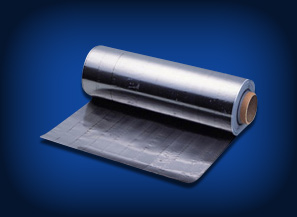

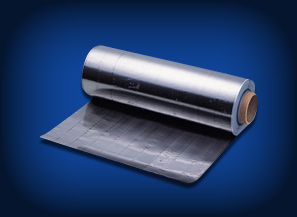

Picture of FINEMET®

through a transmission

electron microscope

Features of FINEMET®

High saturation

flux density

Excellent

temperature

characteristics

Low core loss

High

permeability

High

squareness

Low

magnetostriction

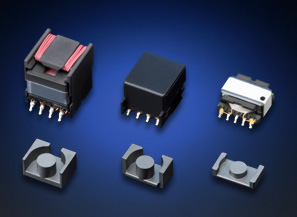

EMI filters/Common mode chokess

Magnetic Shielding Sheets FM SHIELD®

Shield Yoke Sheet for Wireless Chargers

Electromagnetic wave absorbers

Current sensors/Magnetic sensors

Magnetic amplifier

Pulsed power cores

Surge absorbers

High voltage pulse transformers

Low Core Loss Noncut Core

Low Core Loss Cut Cores

Active filters

Smoothing choke coils

Accelerator cavity

Energy

sarving

Volume

reduction

High

performance

Noize

reduction

High

frequency

use

Inquiries

[USA]

Proterial America, Ltd.

2 Manhattanville Road,Suite 301,

Purchase, NY 10577, U.S.A

TEL : +1-914-694-9200

FAX : +1-914-694-9279

[Europe]

Proterial Europe GmbH

Head Office

Immermannstrasse 14-16,

40210 Duesseldorf, Germany

TEL : +49-211-16009-0

FAX : +49-211-16009-60

[Asia]

Proterial Asia Pacific Pte. Ltd.

12 Gul Avenue, Singapore 629656

TEL : +65-6861-7711

FAX : +65-6861-9554

Proterial Hong Kong Limited

8/F., Building 20E, Phase 3, Hong Kong Science Park, Pak Shek Kok, N.T.,

Hong Kong

TEL : +852-2724-4183

Product Catalog Download

Click here to download the product catalog

Contact

Soft Magnetic Materials and Components (for FINEMET® Applied Product and Ribbon)

Major Operation Bases

ABOUT US

Leading sustainability by high performance

768,6

billion

18,877