Environmental Value Produced

Providing Environmental Value As a Green Enabler

Working to provide environmental value at each stage of the manufacturing process as a green enabler, we recognize our role in enabling customers to reduce their environmental impact through our products as a business opportunity. To provide value as a green enabler, we are working to (1) manufacture products using processes that reduce environ-mental impact, and to (2) develop environmentally friendly products.

1 Manufacture and provision of products through processes that reduce environmental impact

We recognize that it is essential to make efforts to reduce environmental impact not only in our own company but also in the value chain. Measures we are advancing include the reduction of CO2 emissions and of the resources used in each process, the promo-tion of recycling, and reduction in the use of harmful substances. We are focusing on these initiatives as we believe that products manufactured in processes that reduce the environmental impact indirectly contribute to reducing the environmental impact in the value chains of our customers who use those products. We also made our Scope 3 calculations based on this belief. Going forward, we will proceed with studies on managing CO2 emissions under Scope 3 based on these calculation results.

-

We give priority to business partners who are working proactively on environmental conservation as well as to materials that have a low environ-mental footprint, such as recycled materials.

Main Initiative

- Expanding the use of recycled raw materials

Examples

- Iron scrap

- Waste from cutting magnets

- Amorphous metals, etc.

Results (FY2023)

- Amount of recycled materials used 505 thousand tons

-

We are engaged in the research, development, and design of products and services that can provide environmental value and lead to sustainable growth and social contribution.

Main Initiative

- Promoting the development of environmentally friendly products that contribute to decarbonization and reduction of energy use over the product life cycle

- Conducting environmentally friendly design assessments, etc. during new product development

Examples

- Developed an amorphous alloy laminated adhesive ribbon for motor cores

- Used ferrite magnet motors to confirm that an output of over 100kW, which is necessary for application to BEV and PHEV traction motors, could be achieved.

Results (FY2023)

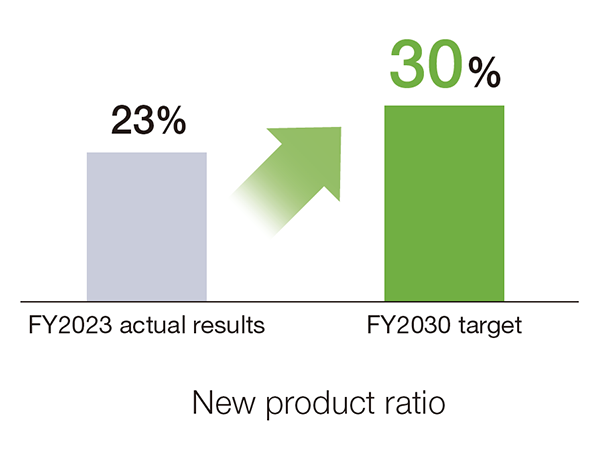

- New product ratio 23%

-

In addition to energy-saving measures, such as optimizing processes and layouts and improv-ing energy efficiency, we are promoting the deployment of renewable energy.

Main Initiative

- Expanding the deployment of renewable energy

- Promotion of energy saving

Examples

- Installation of one of the largest photovoltaic panel installations in Japan

- Use of alternative coke

Results (FY2023)

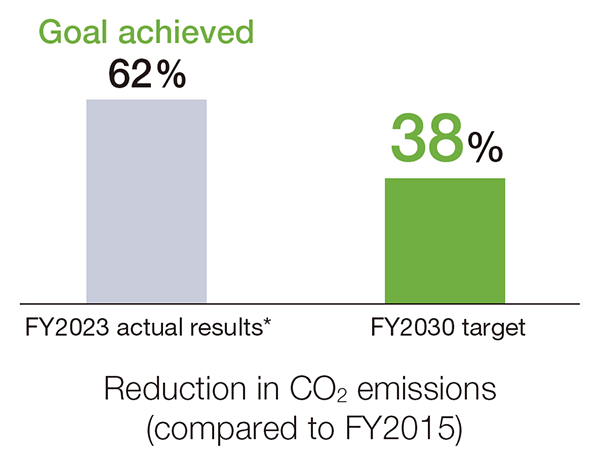

- Reduction in CO2 emissions 62% compared with FY2015

-

Promoting manufacturing that takes life-cycle assessment (LCA) into consideration, we are also working to reduce environmental impact in distribution and sales operations.

Main Initiative

- Reduction of impact on the environment caused by transportation

Examples

- Use of low-emission vehicles

- Improvements to load efficiency

- Reduction of transportation frequency

- Shortening of transportation routes

- Promotion of modal shift

Results (FY2023)

- Improvement rate for reducing the use of energy for transportation by 14.3% compared with the previous fiscal year

-

We contribute to the reduction of environmental load with environmentally friendly products. These products include materials that are essential for xEV manufacturing, materials that reduce power loss, and materials that contribute to the long service lives of our customersʼ products and components.

Main Initiative

- By their use of our environmental-ly friendly products, we are contributing to resolving our customersʼ environmental issues and those in society as a whole.

Results

-

We are actively working on recycling that leads to the effective use of limited resources and to a reduction in the CO2 emissions generated during the manufacturing process.

Main Initiative

- Material recovery and reuse

- Product recovery and reuse

Examples

- Collection and reuse of cutting waste generated on production lines

- Recovery and reuse of amor-phous materials, a major product

Results (FY2023)

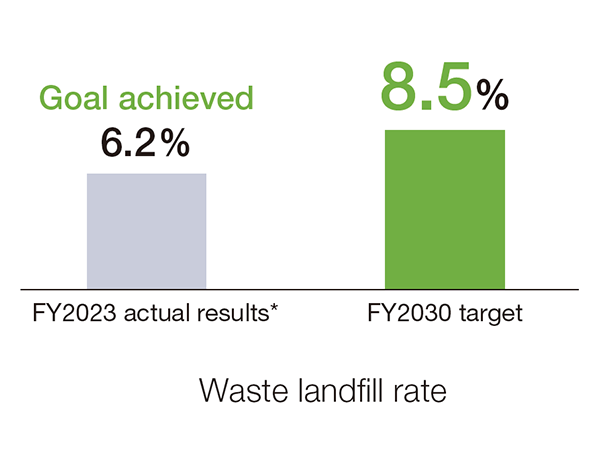

- Improvement rate for reducing the amount of waste, valuables, etc. generated 47.0% compared with FY2010

2 Development of environmentally friendly products

As a green enabler, we promote contributions to society through the provision of environmentally friendly products.

As an environmentally friendly company, Proterial develops products not only from the perspective of reducing the environmental burden during product use but also from the perspective of giving consideration to resource recycling during the manufacturing process.

As an initiative to create environmentally friendly products, we are promoting efforts to implement environmentally friendly design assessments in accordance with the IEC62430 international standard at the start and completion of development in the R&D phase. Involving the use of environmental assessment sheets to evaluate the environmental impact at each product life cycle stage during the R&D and product development phases, environmentally friendly design leads to environmentally friendly products after commercialization.

Product development geared toward reduced environmental impact

- *xEV: A collective term for electric vehicles (EV), hybrid electric vehicles (HEV), and plug-in hybrid electric vehicles (PHEV).