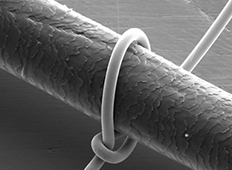

Wire Electric Discharge Machining [EDM]

Our Electric Discharge Machining (EDM) wire is especially designed for cutting hard metals using the EDM process. Featuring superior electric properties, EDM Wire is the first choice for high-speed machining and cutting projects requiring surface precision.

Product Catalog Download

Click here to download the product catalog

Contact

We propose a method to use materials tailored to your company.

Features

- The wire is manufactured and quality-controlled in Japan.

- Many W-EDM machine manufacturers recommend the use of our wire in their machines.

- Stable discharging is enabled with our wire, as carefully selected materials are used.

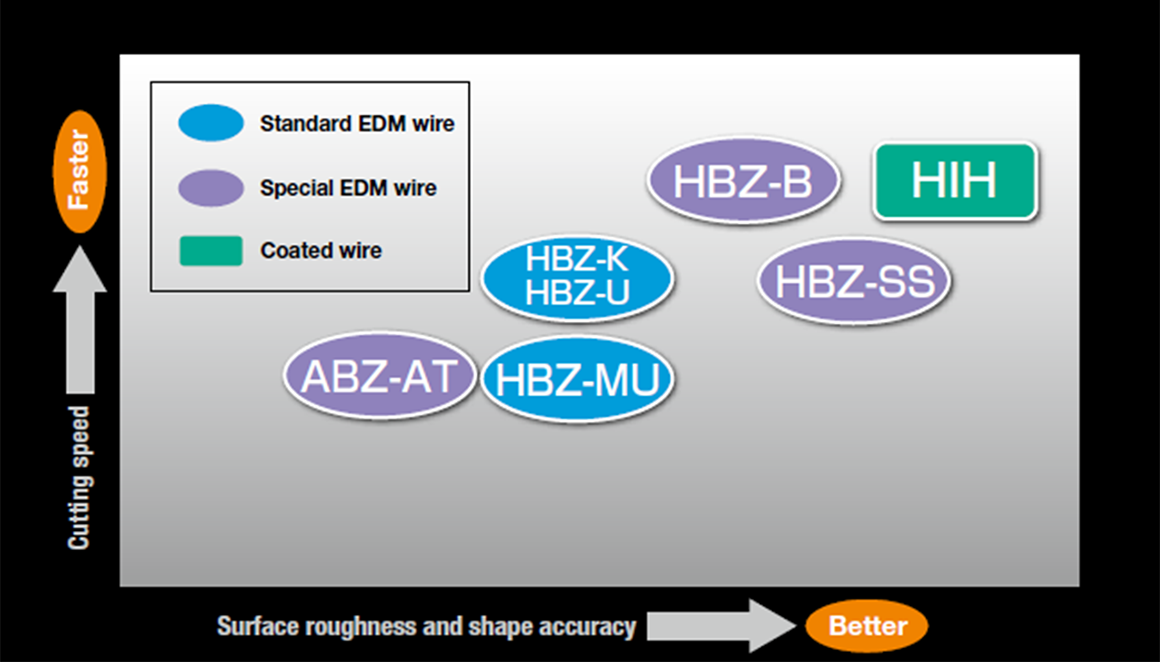

Position of our EDM wire

Introduction of products

Standard EDM Wire

Special EDM wire

Coated EDM wire

Product information

Hard wire

| Product name | Wire size(φmm) | Paraffin wire | Non-Paraffin wire |

|---|---|---|---|

| HBZ-K wire HBZ-U wire |

0.10 | HBZ-U10 | HBZ-U(N)10 |

| 0.15 | HBZ-U15 | HBZ-U(N)15 | |

| 0.20 | HBZ-U20 | HBZ-U(N)20 | |

| 0.25 | HBZ-U25 | HBZ-U(N)25 | |

| 0.30 | HBZ-U30 | HBZ-U(N)30 | |

| 0.40 | HBZ-U40 | HBZ-U(N)40 | |

| HBZ-MU wire | 0.10 | HBZ-MU10 | HBZ-MU(N)10 |

| 0.15 | HBZ-MU15 | HBZ-MU(N)15 | |

| 0.20 | HBZ-MU20 | HBZ-MU(N)20 | |

| 0.25 | HBZ-MU25 | HBZ-MU(N)25 | |

| 0.30 | HBZ-MU30 | HBZ-MU(N)30 | |

| HBZ-B wire | 0.20 | HBZ-B20 | HBZ-B(N)20 |

| 0.25 | HBZ-B25 | HBZ-B(N)25 | |

| 0.30 | HBZ-B30 | HBZ-B(N)30 | |

| HBZ-SS wire | 0.10 | - | HBZ-SS(N)10 |

| 0.15 | - | HBZ-SS(N)15 | |

| 0.20 | - | HBZ-SS(N)20 | |

| 0.25 | - | HBZ-SS(N)25 |

Soft wire

| Product name | Wire size(φmm) | Paraffin wire | Non-Paraffin wire |

|---|---|---|---|

| ABZ wire (Soft) |

0.20 | ABZ20 | ABZ(N)20 |

| 0.25 | ABZ25 | ABZ(N)25 | |

| 0.30 | ABZ30 | ABZ(N)30 | |

| ABZ-AT wire (Extremely Soft) |

0.20 | ABZ-AT20 | ABZ-AT(N)20 |

| 0.25 | ABZ-AT25 | ABZ-AT(N)25 | |

| 0.30 | ABZ-AT30 | ABZ-AT(N)30 |

Coated wire

| Product name | Wire size(φmm) | Paraffin wire | Non-Paraffin wire |

|---|---|---|---|

| HIH wire | 0.10 | HIH10 | HIH(N)10 |

| 0.15 | HIH15 | HIH(N)15 | |

| 0.20 | HIH20 | HIH(N)20 | |

| 0.25 | HIH25 | HIH(N)25 | |

| 0.30 | HIH30 | HIH(N)30 |

Product specification

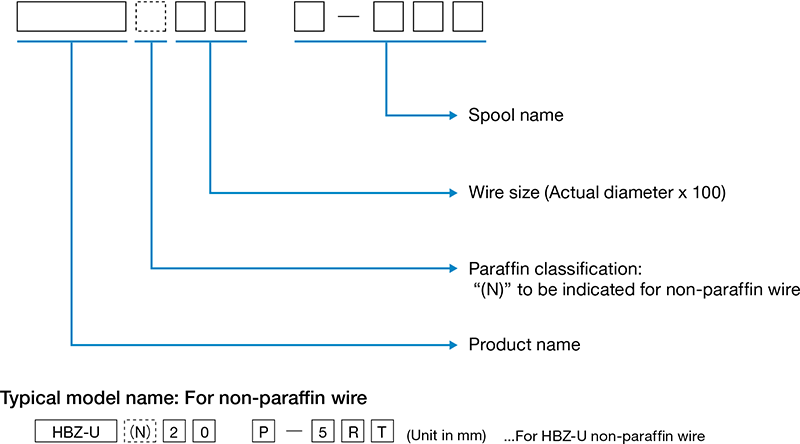

Please place an order according to the following format:

| Product category | Product name | Standard size*1 (φmm/inch) |

Wire tolerance (mm/inch) |

Tensile strength (MPa) |

Elongation (%) |

|---|---|---|---|---|---|

| Standard EDM wire |

0.10/0.004 | ±0.001/±0.00004 | Min 980 | Min 0.4 | |

| 0.15/0.006 | |||||

| 0.20/0.008 | -0.002~0/-0.00008~0 | ||||

| 0.25/0.010 | Min 932 | ||||

| 0.30/0.012 | |||||

| 0.40/0.016 | Min 850 | ||||

| 0.10/0.004 | ±0.001/±0.00004 | Min 980 | Min 0.4 | ||

| 0.15/0.006 | |||||

| 0.20/0.008 | -0.002~0/-0.00008~0 | ||||

| 0.25/0.010 | Min 932 | ||||

| 0.30/0.012 | |||||

| Special EDM wire |

0.20/0.008 | -0.002~0/-0.00008~0 | Min 883 | Min 0.4 | |

| 0.25/0.010 | Min 784 | ||||

| 0.30/0.012 | |||||

| 0.20/0.008 | -0.002~0/-0.00008~0 | Min 441 | Min 15 | ||

| 0.25/0.010 | |||||

| 0.30/0.012 | |||||

| 0.20/0.008 | -0.002~0/-0.00008~0 | Max 490 | Min 25 | ||

| 0.25/0.010 | Max 450 | ||||

| 0.30/0.012 | |||||

| 0.10/0.004 | -0.001~0/-0.00004~0 | Min 980 | Min 0.4 | ||

| 0.15/0.006 | |||||

| 0.20/0.008 | -0.002~0/-0.00008~0 | ||||

| 0.25/0.010 | Min 932 | ||||

| Coated Wire | 0.10/0.004 | ±0.001/±0.00004 | Min 980 | Min 0.4 | |

| 0.15/0.006 | |||||

| 0.20/0.008 | -0.002~0/-0.00008~0 | ||||

| 0.25/0.010 | Min 932 | ||||

| 0.30/0.012 |

- Note:*1 Please contact us for the availability of custom sizes, other than standard sizes.

Q&A about Wire Electric Discharge Machining(EDM)

-

QWhat is the difference between HBZ-U and HBZ-MU ?

-

AMaterial composition differs.

EDM wire is made of brass which is an alloy of copper and zinc.

HBZ-U⇒Cu:60% and Zn:40%

HBZ-MU⇒Cu:65% and Zn:35%

The more zinc composition EDM wire can have more electric discharge,

resulting in better cutting performance.

-

QWhat is the difference between Paraffin wire and Non-Paraffin wire ?

-

AA paraffine wire is that a wire has lubricant paraffin on its surface.

It can help less wire snagging and less brass powder during EDM process.

Our product desicription shows (N) if it is a Non-parrafine wire. (ex.HBZ-U(N)20)

When there is not (N) of its description, it means a Parrafine wire. (ex.HBZ-U20)

-

Qwould like to know the wire length

-

APlease refer the below link about the relations between Spool weight and wire length

Inquiries

[Proterial (India) Private Limited]

Plot No 94 & 95, Sector 8, IMT Manesar, Gurugram, Haryana 122050, India

TEL : +91-124-4812300

[ Proterial Asia Pacific Pte. Ltd. ]

12 Gul Avenue, Singapore 629656

TEL : +65-6861-7711

[Proterial (China), Ltd.]

Room 1501, T1 of Raffles City, No.1133, Chingning Road, Shanghai, 200051, P.R.China

TEL : +86-21-3366-3000

Product Catalog Download

Click here to download the product catalog

Contact

We propose a method to use materials tailored to your company.

Other products

Products & Solutions

ABOUT US

Leading sustainability by high performance

Revenues

768,6

billion

Employees

18,877