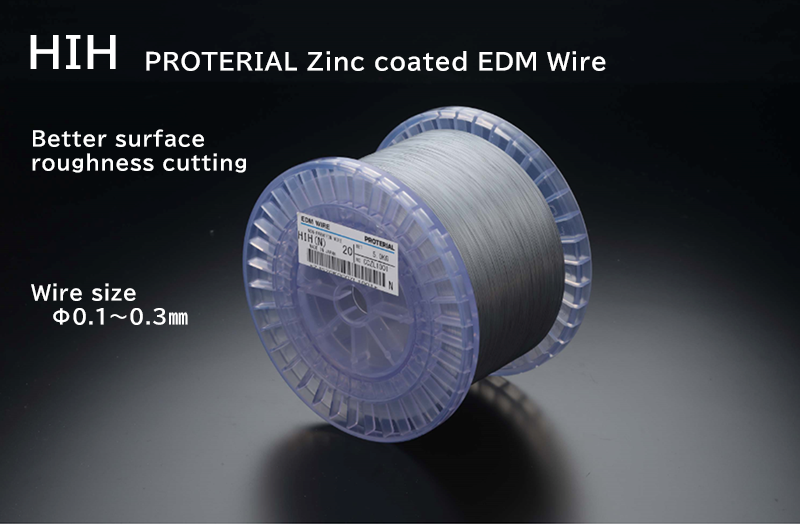

<HIH>

Better surface roughness cutting

Coated EDM wire

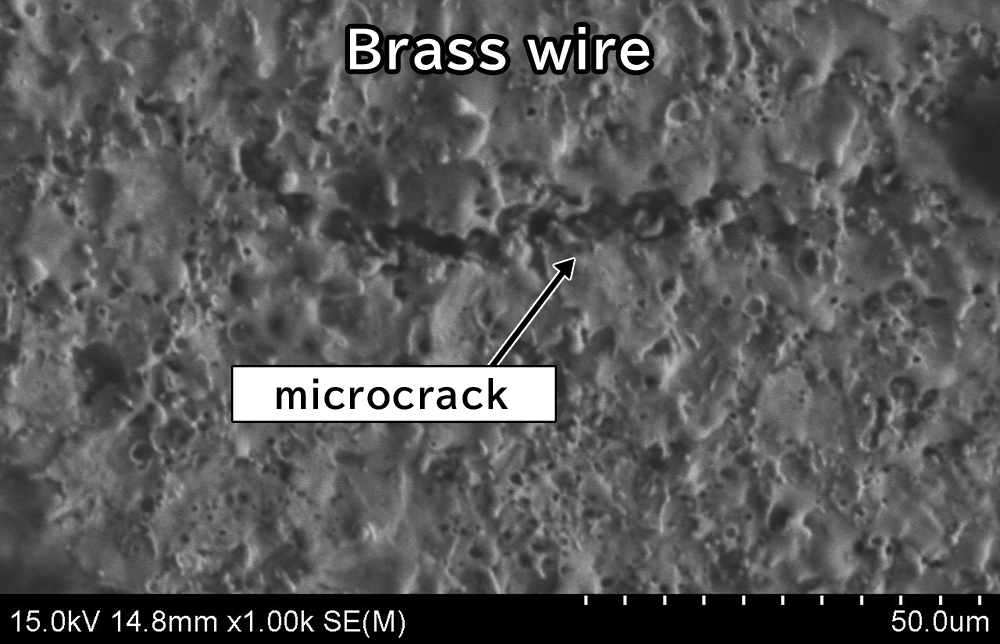

- Improvement in surface accuracy

- Zinc powder reduction

- Brass adhesion prevention

- Hard wire

- Effective for better surface roughness and form accuracy

- Stable and constant discharge performance by uniform Zinc coating

- Reducing thermal stress to workpiece during EDM process,

and contributing to longer life of press mold

Product Catalog Download

Click here to download the product catalog

Contact

We propose a method to use materials tailored to your company.

General characteristics of HIH wire

| Product name | Standard size*1 (φmm/inch) |

Wire tolerance (mm/inch) |

Tensile strength (MPa) |

Elongation (%) |

|---|---|---|---|---|

| HIH | 0.10/0.004 | ±0.001/±0.00004 | Min 980 | Min 0.4 |

| 0.15/0.006 | ||||

| 0.20/0.008 | -0.002~0/ -0.00008~0 |

|||

| 0.25/0.010 | Min 932 | |||

| 0.30/0.012 |

- Note:*1 Please contact us for the availability of custom sizes, other than standard sizes.

- The paraffin or non-paraffin type is specifiable. Please see “Table for checking paraffin presence” on page 3 for applicable W-EDM machines.

Cutting surface

Wire length of HIH

| Weight | Wire size(Φmm) | ||||

|---|---|---|---|---|---|

| 0.10 | 0.15 | 0.20 | 0.25 | 0.30 | |

| 3kg | 45,097m | 20,043m | 11,274m | 7,216m | 5,011m |

| 5kg | - | 33,405m | 18,790m | 12,026m | 8,351m |

| 10kg | - | - | 37,581m | 24,052m | 16,703m |

| 15kg | - | - | 56,371m | 36,078m | 25,054m |

| 20kg | - | - | 75,162m | 48,103m | 33,405m |

| 30kg | - | - | 112,742m | 72,155m | 50,108m |

| 50kg | - | - | 187,904m | 120,258m | 83,513m |

Product Catalog Download

Click here to download the product catalog

Contact

We propose a method to use materials tailored to your company.

ABOUT US

Leading sustainability by high performance

Revenues

768,6

billion

Employees

18,877