Lineup for high frequency coaxial cable

Electric Wire & Cable Business Unit

Properties

| *PFAS free |

Sub- milimater wave transmission |

Bending application |

UL style |

# | AWG size |

Nom. Capacitance | Chracteristic impedance |

Nom. Attenuation | Nom. Time delay | Conductor resistance |

Operating temperature |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1GHz | 5GHz | 20GHz | |||||||||||

| - | pF/m | Ω | dB/m | dB/m | dB/m | ns/m | Ω/km | °C | |||||

| - | ✓ | - | - | 1 | 24 | 95 | 50±2 | 0.8 | 2.2 | 6.1 | 4.8 | Max. 91 | -40~150 |

| ✓ | ✓ | - | - | 2 | 24 | 95 | 50±2 | 0.8 | 2.2 | 6.2 | 5 | Max. 91 | * |

| - | ✓ | - | - | 3 | 26 | 95 | 50±2 | 1 | 2.6 | 7 | 4.8 | Max. 145 | -40~150 |

| ✓ | ✓ | - | - | 4 | 26 | 95 | 50±2 | 1 | 2.6 | 7 | 5 | Max. 145 | * |

| - | ✓ | - | - | 5 | 28 | 95 | 50±2 | 1.1 | 2.9 | 7.2 | 4.8 | Max. 235 | -40~150 |

| ✓ | ✓ | - | - | 6 | 28 | 95 | 50±2 | 1.1 | 2.9 | 7.3 | 5 | Max. 235 | * |

| - | ✓ | - | - | 7 | 29 | 95 | 50±2 | 1.3 | 2.9 | 7.3 | 4.8 | Max. 265 | -40~150 |

| ✓ | ✓ | - | - | 8 | 29 | 95 | 50±2 | 1.3 | 2.9 | 7.5 | 5 | Max. 265 | * |

| - | - | - | 1745 | 9 | 30 | 95 | 50±2 | 1.5 | 3.8 | - | 4.8 | Max. 326 | -40~90 |

| - | - | - | 1745 | 10 | 32 | 95 | 50±2 | 2 | 4.7 | - | 4.8 | Max. 597 | -40~90 |

| - | - | - | 1745 | 11 | 32 | 95 | 50±2 | 2 | 4.7 | - | 4.8 | Max. 597 | -40~90 |

| - | - | - | 1745 | 12 | 32 | 95 | 50±2 | 2 | 4.7 | - | 4.8 | Max. 597 | -40~90 |

| - | - | - | 1745 | 13 | 34 | 100 | 50±5 | 2.6 | 7 | - | 4.8 | Max. 868 | -40~90 |

| - | - | - | 1745 | 14 | 36 | 100 | 50±3 | 3.1 | 8.2 | - | 4.8 | Max. 1,400 | -40~90 |

| - | - | - | 1354 | 15 | 36 | 100 | 50+2-1 | 3.1 | 8.2 | - | 4.8 | Max. 1,400 | -40~90 |

| - | - | - | - | 16 | 37 | 100 | 50±2.5 | 3.3 | 8.4 | - | 4.8 | Max. 1,750 | -40~150 |

| - | - | - | - | 17 | 38 | 100 | 50±2.5 | 3.7 | 8.7 | - | 4.8 | Max. 1,900 | -40~150 |

| - | - | ✓ | - | 18 | 40 | 100 | 50±2.5 | 5.2 | * | - | 4.8 | Max. 4,200 | -40~150 |

| - | - | ✓ | - | 19 | 42 | 110 | 50±2.5 | 6.2 | * | - | 4.8 | Max. 7,500 | -40~150 |

| - | - | ✓ | - | 20 | 44 | 110 | 50±2.5 | 7.8 | * | - | 4.8 | Max. 9,700 | -40~150 |

| - | - | ✓ | - | 21 | 46 | 115 | 50±2.5 | 9.9 | * | - | 4.8 | Max. 14,500 | -40~150 |

| - | - | ✓ | - | 22 | 48 | 120 | 50±5 | * | * | - | 4.8 | Max. 23,000 | -40~150 |

| - | - | ✓ | - | 23 | 50 | 120 | 50±5 | * | * | - | 4.8 | Max. 37,500 | -40~150 |

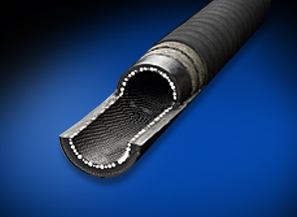

Construction

| *PFAS free |

Sub- milimater wave transmission |

Bending application |

UL style |

# | Inner conductor | Insulation | Outer conductor | Jacket | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AWG size |

Material | Nom. O.D. |

Material | Nom. O.D. |

Type | Material | Nom. O.D. |

Material | Nom. O.D. |

|||||

| - | - | mm | - | mm | - | - | mm | - | mm | |||||

| - | ✓ | - | - | 1 | 24 | GAA | 0.511 | Fluolinated polymer |

1.63 | SX | GAA | 1.87 | Fluolinated polymer |

2.17 |

| ✓ | ✓ | - | - | 2 | 24 | GAA | 0.511 | Non- Fluolinated polymer |

1.71 | SX | GAA | 1.95 | Non- Fluolinated polymer |

2.01 |

| - | ✓ | - | - | 3 | 26 | GAA | 0.404 | Fluolinated polymer |

1.27 | SX | GAA | 1.51 | Fluolinated polymer |

1.81 |

| ✓ | ✓ | - | - | 4 | 26 | GAA | 0.404 | Non- Fluolinated polymer |

1.33 | SX | GAA | 1.57 | Non- Fluolinated polymer |

1.63 |

| - | ✓ | - | - | 5 | 28 | GAA | 0.32 | Fluolinated polymer |

0.99 | SX | GAA | 1.23 | Fluolinated polymer |

1.53 |

| ✓ | ✓ | - | - | 6 | 28 | GAA | 0.32 | Non- Fluolinated polymer |

1.04 | SX | GAA | 1.3 | Non- Fluolinated polymer |

1.36 |

| - | ✓ | - | - | 7 | 29 | GAA | 0.3 | Fluolinated polymer |

0.97 | SX | GAA | 1.21 | Fluolinated polymer |

1.37 |

| ✓ | ✓ | - | - | 8 | 29 | GAA | 0.3 | Non- Fluolinated polymer |

0.97 | SX | GAA | 1.21 | Non- Fluolinated polymer |

1.34 |

| - | - | - | 1745 | 9 | 30 | GAA | 0.306 | Fluolinated polymer |

0.88 | SB | TA | 1.1 | Fluolinated polymer |

1.37 |

| - | - | - | 1745 | 10 | 32 | GAA | 0.24 | Fluolinated polymer |

0.68 | SB | GAA | 0.88 | Fluolinated polymer |

1.13 |

| - | - | - | 1745 | 11 | 32 | GAA | 0.24 | Fluolinated polymer |

0.68 | SB | GAA | 0.88 | Fluolinated polymer |

1.32 |

| - | - | - | 1745 | 12 | 32 | GAA | 0.24 | Fluolinated polymer |

0.68 | DSB | TA | 1.12 | Fluolinated polymer |

1.32 |

| - | - | - | 1745 | 13 | 34 | GAA | 0.192 | Fluolinated polymer |

0.53 | SB | TA | 0.78 | Fluolinated polymer |

0.98 |

| - | - | - | 1745 | 14 | 36 | GAA | 0.15 | Fluolinated polymer |

0.4 | SB | GAA | 0.65 | Fluolinated polymer |

0.81 |

| - | - | - | 1354 | 15 | 36 | GAA | 0.15 | Fluolinated polymer |

0.44 | SW | TA | 0.54 | Fluolinated polymer |

0.64 |

| - | - | - | - | 16 | 37 | GAH | 0.12 | Fluolinated polymer |

0.36 | SW | TH | 0.42 | Fluolinated polymer |

0.48 |

| - | - | - | - | 17 | 38 | GAH | 0.12 | Fluolinated polymer |

0.345 | SW | TH | 0.41 | Fluolinated polymer |

0.48 |

| - | - | ✓ | - | 18 | 40 | SPCA | 0.09 | Fluolinated polymer |

0.25 | SW | TH | 0.31 | Fluolinated polymer |

0.37 |

| - | - | ✓ | - | 19 | 42 | SPCA | 0.075 | Fluolinated polymer |

0.205 | SW | TH | 0.255 | Fluolinated polymer |

0.31 |

| - | - | ✓ | - | 20 | 44 | SPCA | 0.06 | Fluolinated polymer |

0.166 | SW | SPCA | 0.206 | Fluolinated polymer |

0.25 |

| - | - | ✓ | - | 21 | 46 | SPCA | 0.048 | Fluolinated polymer |

0.124 | SW | SPCA | 0.164 | Fluolinated polymer |

0.208 |

| - | - | ✓ | - | 22 | 48 | SPCA | 0.039 | Fluolinated polymer |

0.099 | SW | SPCA | 0.139 | Fluolinated polymer |

0.181 |

| - | - | ✓ | - | 23 | 50 | SPCA | 0.03 | Fluolinated polymer |

0.072 | SW | SPCA | 0.106 | Fluolinated polymer |

0.146 |

TA:Tinned annealed copper TH:Tinned hard drawn copper GAA:Silver plated annealed copper GAH:Silver plated hard drawn copper SPCA: Silver plated copper alloy

SB: Braid shielding DSB: Double layer braiding shield SW: spiral shielding SX: Special braid shielding

- *Ask contact person for assurance content.

Feature

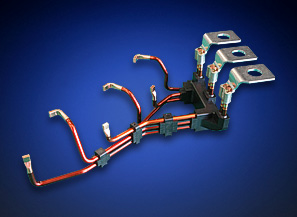

- Supply record for electronical equipment, medical devices etc.

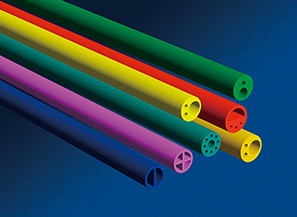

- We can offer wide range of conductor size.

- Customized cable can be achieved by original material and design technique.

- PFAS free design

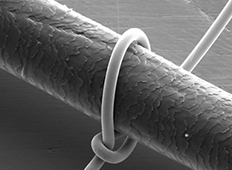

- Flexible part design-bending/torsion resistance-

- Milimeter wave transmission

- Impedance / capacitance matching for requested value

- High temperature / extra low temperature design

Electric Wire & Cable Business Unit

Other products

Products & Solutions

ABOUT US

Leading sustainability by high performance

Revenues

768,6

billion

Employees

18,877