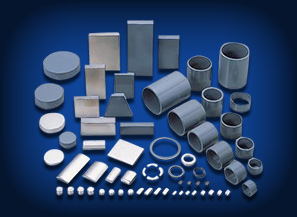

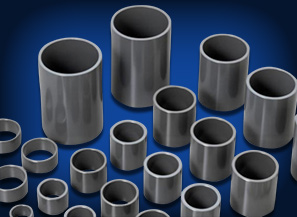

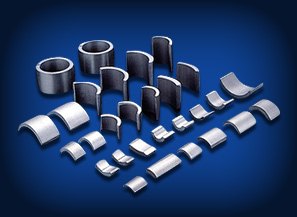

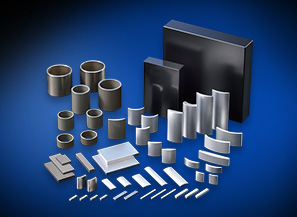

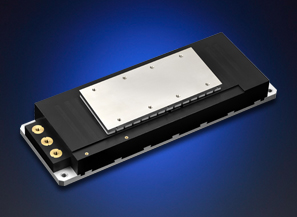

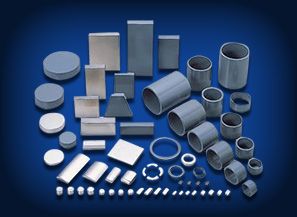

Nd-Fe-B Magnets NEOMAX®

It has the best magnetic properties of any practical magnet, and contributes to the miniaturization, weight reduction, high output, high efficiency and energy saving of products. It plays an important role as a material indispensable to society.

We also provide comprehensive design support, proposing the most suitable materials and shapes to meet customer requests.

Furthermore, we have succeeded in developing and mass-producing the high-performance, heavy rare earth-saving material, which minimizes the amount of heavy rare earth elements added, such as dysprosium (Dy) and terbium (Tb).

We will continue to address resource risk.

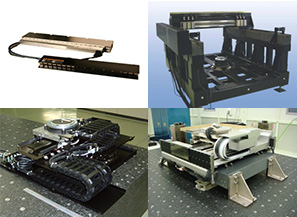

We propose a method to use materials tailored to your company.

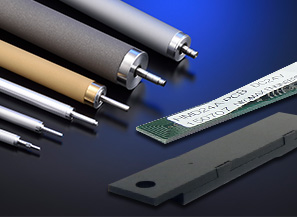

Surface Treatment Technology

We offer a lineup of highly functional surface treatments (metal/resin) to meet the needs of a variety of usage environments. All of the surface treatments are excellent in corrosion resistance and adhesion. We offer aluminum coating, which has excellent adhesive endurance, nickel plating, which has a smooth surface and high film hardness, and epoxy coating, which has excellent insulation properties. In addition, M-1 coating, which uses our unique oxide film processing technology on the magnet surface, is slightly less corrosion resistant, but is popular for applications such as immersion in oil or refrigerants.

Our surface treatments comply with the RoHS/ELV directive and other international environmental standards.

| Aluminum coating | Nickel plating | Epoxy coating | Passivation (M-1) | ||

|---|---|---|---|---|---|

| Standard coating thickness (μm) |

≧2 | ≧5 | ≧7 | - | |

| Corrosion resistance | Thermal humidity resistance | ○ | ◎ | ○ | |

| Salt spray resistance | ○ | ◎ | |||

| Adhesive endurance | ◎ | ○ | |||

| Insulation | ◎ | ||||

| Application examples | Motors, Sensors, Actuators |

VCM, Sensors, Optical pickups, Small actuators |

xEV traction motors/generators, Electric power steering, Various motors |

Compressor motors, xEV traction motors/generators |

|

- ◎: Recommended ○: Fair

- Various surface treatments are standard specifications and film thicknesses are standard values.

- Please consult us for special specifications according to the application, operating environment, etc.

Appearance

Basic Precautions Before Using Magnets

Magnetic Materials Business Unit

ABOUT US

Leading sustainability by high performance

768,6

billion

18,877