Aluminum Electroplating Technology ALectro™

The characteristic values, photographs, charts, rankings, evaluations, etc. shown on this page are representative values based on our test data and do not guarantee the quality of the products. The information on this page is subject to change without notice.

We provide services tailored to your company's issues and needs.

Contents

What is ALectro™?

ALectro™ is a technology for electrolytic deposition of aluminum, in other words, an aluminum electroplating technology. The term "ALectro" was coined from the words, aluminum and electroplating.

Aluminum electroplating has been considered difficult because aluminum cannot be plated with an electrolyte that uses an aqueous solution. Therefore, we focused on electrolytes using organic compounds and developed ALectro™, an electroplating technology. With ALectro™, it is possible to coat various substrates with aluminum.

Appearance Changes of Metal Substrates with ALectro™

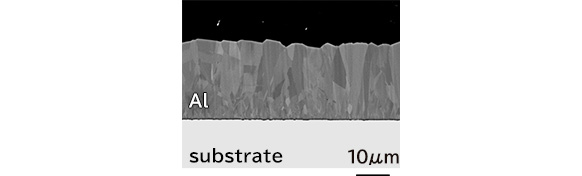

Cross-section of Substrate Coated with ALectro™

The aluminum film formed by ALectro™ consists of columnar crystals aligned vertically to the in-plane direction of the substrate.

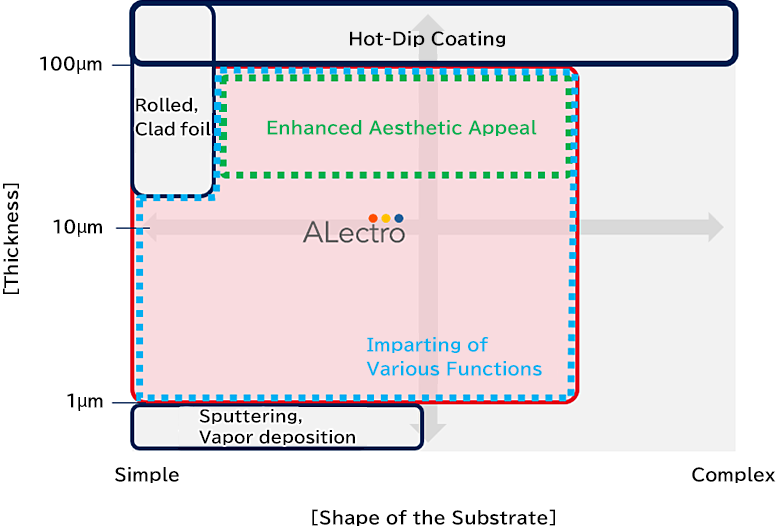

Comparison of ALectro™ with other Aluminum Coating Technologies

ALectro™ can form layers thicker than vapor deposition or sputtering, and thinner than hot-dip coating or rolled/clad foil.

Substrate that has simple shape(i.e. flat plate) can be easily coated, as well as those have slightly more complex shapes.

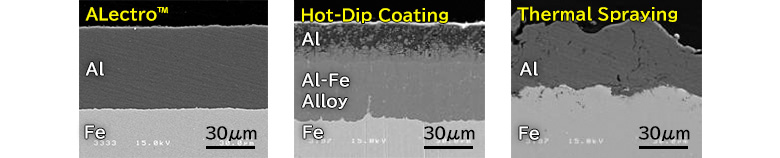

Comparison of Fe Substrate Cross-Sections Coated with Aluminum Using Various Methods

Compared to other aluminum coating methods, ALectro™ can form a dense and uniform aluminum layer.

Characteristics of ALectro™

| Characteristics | Properties of ALectro™ |

|---|---|

| Purity | >99.0 mass% |

| Thickness | 3 - 100μm |

| Surface Roughness (Ra) | Approximately 0.1~0.6μm |

| Volume Resistivity | 3.1μΩ・cm (Equivalent to pure Al*) |

| Electroplatable Substrate Materials | Various metals and some resins [Materials with verified plating] Metals: Mg, Fe, Cu, Al, Ti, Ni, Zn, SUS Resins: CFRP |

| Substrate Shape | Simple shapes (plates, foils, etc.) – Can be supported Complex shapes - Consultation required |

Aesthetic Appearance of Products with ALectro™

Substrate’s Surface Coated with ALectro™

The surface of substrate coated with ALectro™ exhibits a luxurious matte texture and an aesthetic white color. The matte texture is due to the fine roughness on the surface that causes light to scatter. The surface treated with ALectro™ can achieve a metallic luster through polishing.

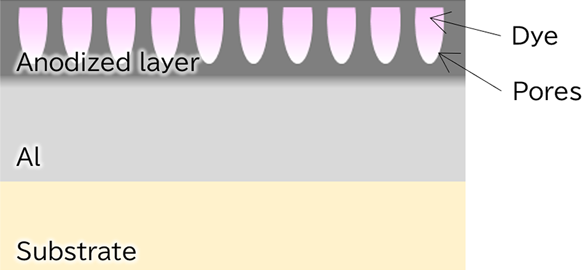

Cross-sectional Schematic Diagram of Substrate Treated with ALectro™ and Color Anodizing

Color anodizing allows for free coloring. This enables the realization of aesthetic colors while retaining the metallic texture of aluminum. Using ALectro™, both metal and resin substrates can be colored through anodizing process. There are several other methods to enhance design features, but ALectro™ combined with color anodizing can eliminate the need for painting, thereby reducing volatile organic compounds (VOCs) and improving production yield.

Anodized layer has open pores that can absorb dyes. Subsequently, a sealing process traps the dye within the pores. Through this process, the substrate treated with ALectro™ can be colored in any desired color.

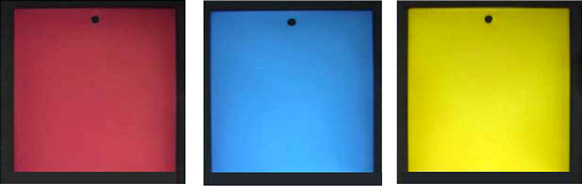

Appearance of Substrates Color-Anodized After ALectro™

It is possible to add design such as text and images, as well as to color the entire surface.

Improvement of Corrosion Resistance with ALectro™

ALectro™ provides a long-term protection of your products against rust and deterioration.

Combining it with methods that form oxide films, such as anodizing, can further enhance corrosion resistance.

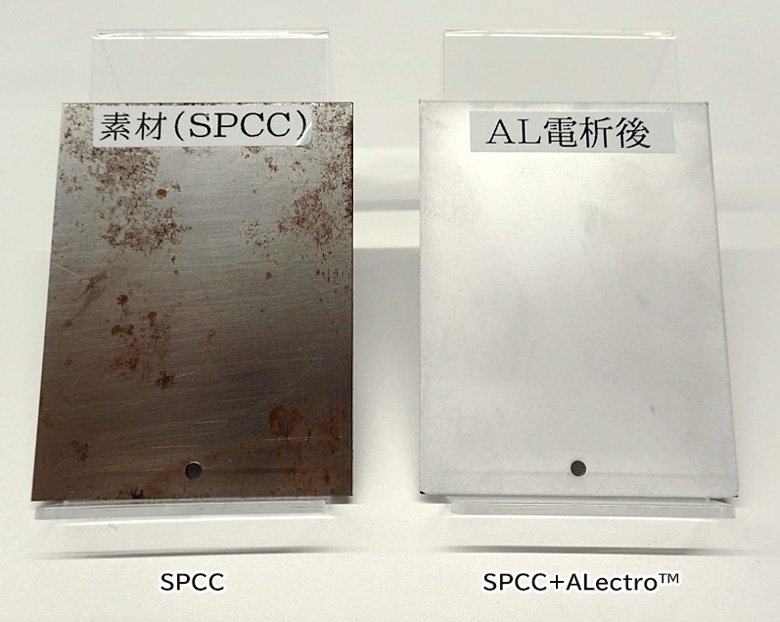

Appearance of SPCC (Steel Plate Cold Commercial) Coated with ALectro™ After Being Exposed to the Atmosphere for Over 10 Years

Surface of SPCC material (on the left) without aluminum coating has rusts, whereas the surface of a SPCC (on the right) coated with aluminum using ALectro™ shows no sign of rusts. Both materials were exposed to the atmosphere for over 10 years.

Functional Foil/Film of ALectro™

Using ALectro™, aluminum can be coated onto foil/film substrates. The aluminum-coated foil/film can be applied to current collector foils for secondary batteries and capacitors.

Appearance of Copper Foil Coated with Aluminum using ALectro™

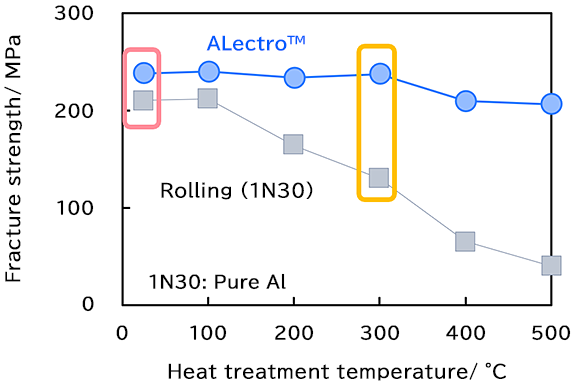

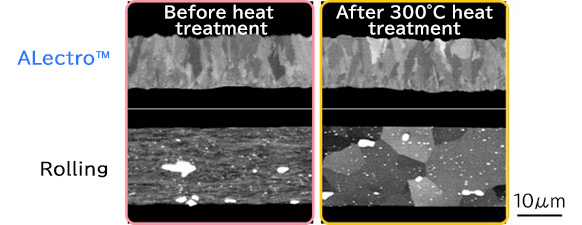

Tensile Strength and Cross-Sectional SEM Images of Aluminum Foil Before and After Heat Treatment

The aluminum film formed by ALectro™ can be used as an aluminum foil by stripping it off from the substrate. The aluminum foil produced by ALectro™ has the characteristic of maintaining its material structure and strength even after heat treatment.

Technical Literature of ALectro™

For more information on the technical content of ALectro™, please refer to the following:

- Properties of Electroplated Aluminum Thin Films

- Characteristics of Dimethyl Sulfone-Based Electrolyte for Aluminum Electrodeposition

- Preparation of Aluminum Foil by an Electrodeposition Method and Its Characterization

- Effect of Ammonium Salts on the Conductivity and Current Efficiency of Dimethyl Sulfone-Aluminum Choride Electrolytes

- News Releases on ALectro™

Prototype Requests/Seeking Collaboration Partners

ALectro™ has a potential to be applied to various industries and products, including electronic devices, exterior parts, transportation equipment, and audio equipment.

Potential Applications Examples:

- Providing corrosion resistance to Magnesium alloys

- Adding aesthetic features to aluminum die-casting

- Adding electrical conductivity to resin films, etc.

We are currently accepting prototype requests and seeking partners to collaborate on mass production of ALectro™. Please feel free to contact us.

Let’s create new business together!

We provide services tailored to your company's issues and needs.

ABOUT US

Leading sustainability by high performance

768,6

billion

18,877