Commencement of Licensing of ALectro™, a Technology for the Electrodeposition of High-purity Aluminum

Proterial, Ltd.

Proterial, Ltd. (hereinafter, Proterial) has begun licensing ALectro, a technology for high-purity aluminum electrodeposition*1, which is an aluminum electroplating method. This technology enables high-purity aluminum films and foils to be formed, helping to enhance the functions of devices with high electrical and thermal conductivity as properties of aluminum. It also improves the corrosion resistance and aesthetic quality of base materials on which films are formed. Proterial will exhibit this technology at the 4th Sustainable Materials Expo to be held at Makuhari Messe starting on October 29.

1.Background

Aluminum is lighter compared with other metal materials and has high electrical and thermal conductivity and corrosion resistance, among other properties. Because of this, it is used in a range of industrial fields including mobility, electronic equipment, and construction materials. Above all, the vapor deposition method*2, with which the base material surface is coated with an aluminum film, makes it possible to enhance the corrosion resistance and optical and electrical properties of the base material by depositing aluminum with thickness of up to 1 μm. It is therefore used for packaging materials, optical equipment, and electronic parts, among other applications. Due to these excellent properties, the demand for aluminum coating has been growing. In particular, a technology for depositing thick aluminum film on the base material surface, which enables to leverage more of aluminum's properties, had been demanded.

2.Outline

Proterial has developed and begun licensing ALectro, an innovative aluminum electrodeposition technology that makes it possible to deposit high-purity aluminum films with thickness of several micrometers to tens of micrometers on the base material, something that is difficult to achieve with the vapor deposition method.

ALectro makes it possible to deposit thick aluminum film not only on metal base materials but also on lightweight base materials such as some resins and carbon-fiber-reinforced plastics. It also features great flexibility in terms of base material shape, permitting the deposition of thick aluminum film not only on flat surfaces, such as foil and film, but also on structural objects. Application of ALectro permits use of aluminum properties, including high electrical and thermal conductivity and corrosion resistance, for diverse purposes, improving the functions of devices and the corrosion resistance of base materials. Further, coloring the aluminum-coated surface of the base material with anodizing*3 treatment enables the addition of aesthetic quality to the appearance while reducing painting processes.

Proterial will license the overall ALectro aluminum electrodeposition technology, including optimal plating conditions and device configurations, so as to help customers solve their issues. Proterial will exhibit the ALectro aluminum electrodeposition technology at the 4th Sustainable Materials Expo to be held at Makuhari Messe starting on October 29, 2024.

| Approach | ALectro | Deposition |

|---|---|---|

| Purity(mass%) | >99.0 | >99.0 |

| Film thickness (μm) | 3-100 | <1 |

| Surface roughness Sa (μm) | >0.10 | <0.10 |

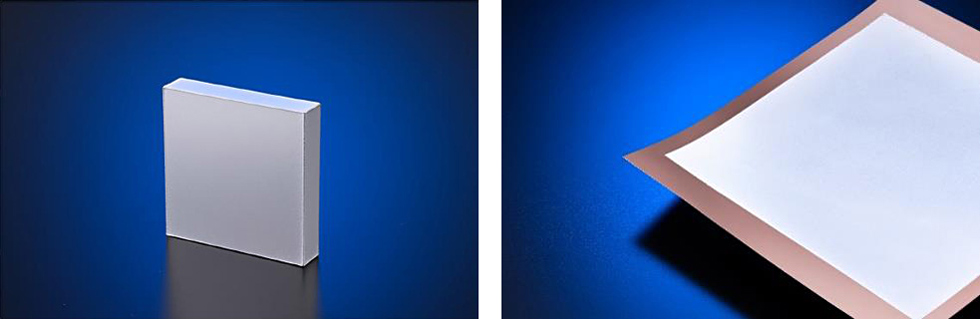

(The white part is the electrodeposited aluminum)

(Left: A metal block whose entire surface is coated by applying ALectro,

Right: A copper foil coated by applying ALectro)

3.Patents

Applications filed internationally

- Media Inquiries: Corporate Communications Dept.

Web inquiry form

ALectro is a trademark of Proterial, Ltd.

- *1A phenomenon in which a metal is deposited and forms a coating electrochemically: electroplating.

- *2A method by which a metal is heated and evaporated in a high vacuum and the steam is attached to the base material surface to deposit a thin film of the metal on it.

- *3A treatment by which an oxidized coating is artificially generated on an aluminum surface through an electrochemical reaction. A coating is generated by soaking the aluminum in a solution for electrolysis. A product can be colored arbitrarily by absorbing a colorant into the oxidized coating.