Roll Bearing Made of Sialon Ceramics In Continuous Galvanizing Pot

Roll Business Unit

Explanation of Product

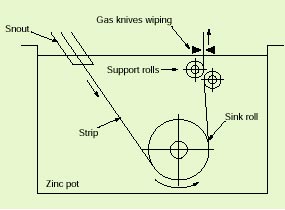

Figure 1 is a diagram of the continuous submerged fusion galvanizing process. The direction of a steel plate submerged in a zinc pot at 460°C-480°C is changed by the sink roll positioned near the central bottom portion of the pot, and the support rolls also positioned in the pot reduce the vibration of the plate and monitor and control its direction.

Figure 1: The Continuous Submerged Fusion Galvanizing Process

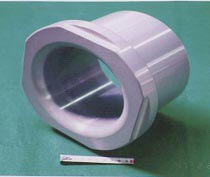

The use of sialon was considered for the bearings of support rolls and sink rolls. Figure 2 shows sialon sink roll bearings.

Figure 2: Sialon Sink Roll Bearings

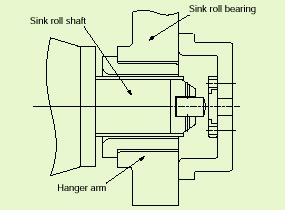

To prevent breakage of the sialon adapted for this purpose, a new shape was designed to prevent core slippage, interstices were installed in the bearings and standard maintenance procedures were established for re-assembly. Figure 3 shows the standard configuration for sink roll bearings when adapted for Sialon shafts.

Figure 3: Structure of Sink Roll Bearings

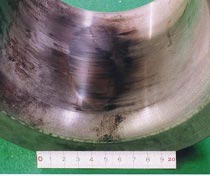

As shown in Figure 4, practical use has shown that sialon bearings show little wear, and, due to their smoothness, there is little abrasion between these bearings and the shafts. Chart 1 shows a comparison of the average radial abrasion loss and wear and abrasion resistance of Sialon and WC-Co molten sprayed material, which is what was conventionally used. This comparison is for when conventional WC-Co molten sprayed material was used for roll shafts. As shown in Chart 1, the use of Sialon for bearings greatly increased wear and abrasion resistance. As a result of the introduction of Sialon bearings, bearing life was significantly increased, line speed was improved and A their introduction eliminates submerged bar replacement caused by bearings, increases operation days and significantly improves productivity.

Figure 4: View of Bearing Following Use

| Chart 1: Comparison of Wear and Abrasion Resistance | |||

|---|---|---|---|

| Average radial abrasion loss (mm per day) | Comparison of wear and abrasion resistance (thermal sprayed material/Sialon) |

||

| Sialon | WC-Co thermal sprayed material | ||

| Support roll bearing | 0.0005 | 0.30~0.50 | Approx. 1,000 times |

| Sink roll bearing | 0.0017 | 0.33 | Approx. 200 times |

Roll Business Unit

ABOUT US

Leading sustainability by high performance

768,6

billion

18,877