Sialon Ceramics for Handling Molten Aluminum

Roll Business Unit

Sialon Parts for Handling Molten Aluminum

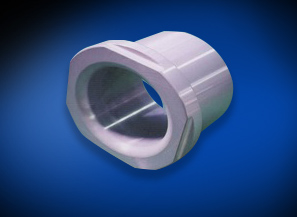

Thermocouple Protection Tube for Measurement of Aluminum Temperature

Figure 1: Sialon protection tube-single pieces

Standard Size(mm)

| Outer Diameter | Inner Diameter | Length |

|---|---|---|

| 11.5 | 6.5 | 500 |

| 15 | 9 | 800 |

| 22 | 14 | 1,100 |

| 28 | 16 | 1,100 |

| 32 | 20 | 1,100 |

| 34 | 20 | 1,900 |

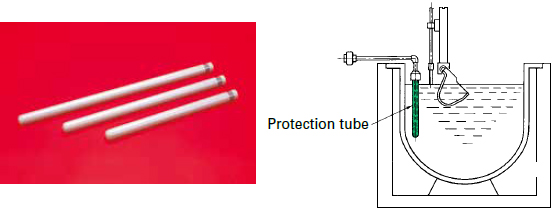

Stalk for Low-Pressure Casting Machines

We offer a line-up of stalks and thermocouple protection tubes, as Sialon parts for lowpressure casting machines.

Also, we are attempting to create a good seal against air leakage by making use of a composite metal and Sialon structure so as to maintain the required die load and prevent breakage.

- Sizes available

- Outer diameter (mm) : Max 234 dia.

Length (mm) : Max 1,400

Figure 2: Stalk

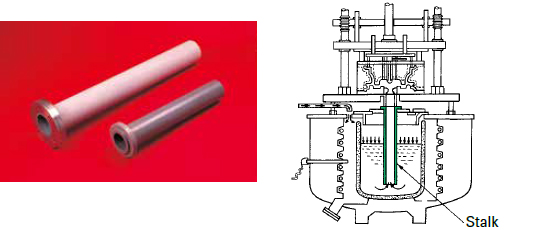

Immersion Heater Tube for Holding Furnaces

Especially useful for disposition of Na fluxes. Applicable to such heat sources as gas burners and electric heaters.

- Sizes available

- Outer diameter (mm) : Max 300 dia.

Length (mm) : Max 1,600

Figure 3: Heater tube

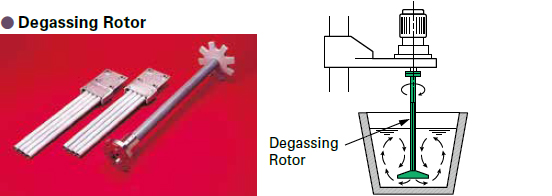

Degassing Rotor for Molten Aluminum

- Sizes available

- Outer diameter (mm) : Max 240 dia

Length (mm) : Max 1,300

Figure 4: Degassing Rotor

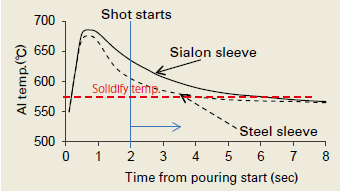

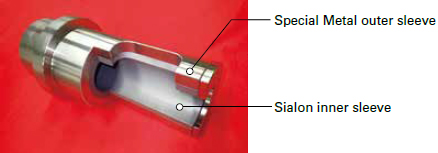

Shot Sleeve for High-Pressure Diecasting Machines

- 1Reduce Cold Flakes ("Cold Flakes") :solidified aluminum defect pieces (scattered structure) formed in shot sleeve

Superior heat-retention. "Possibility of no heating equipment"

- 2Stable shots and longer life (Especially at High temperature ≧ 700℃ or 1290℉)

Less deformation, High corrosion resistance, Erosion resistance and Wear resistance. "Possibility of no water cooling channel"

- 3Energy saving

Sialon's superior heat-retention enables lower molten aluminum casting temperature.

Figure 5: Heat-retention

Figure 6: Shot Sleeve (Cut Model)

Sialon and Super Sialon

Proterial's Sialon and Super Sialon are ideal for jigs and tools that come into direct contact with molten aluminum on the aluminum melting and casting line.

Proterial has developed this heat-resisting, highstrength ceramic material based on its long experience in processing metals, and has used it in molten aluminumhandling parts.

Features of Sialon and Super Sialon Parts for Handling Molten Aluminum

- 1Little or no contamination of molten aluminum.

- 2Little or no corrosion from molten aluminum.

- 3Little or no adherence of molten aluminum.

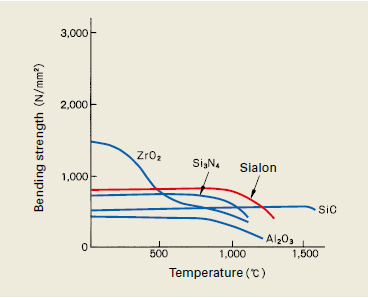

- 4High strength remaining intact within the temperature range of molten aluminum.

- 5Two different thermal conductivity

Low thermal conductivity : Sialon is for higher heat retention required parts such as Stalk.

High thermal conductivity : Super Sialon is for higher heat transfer required parts such as Heater Tube

Characteristics of Sialon

| Materials | Density (g/cm3) |

4 point Bending strength (MPa) |

Young's modules (GPa) |

Thermal shock resistance(ΔT℃) |

Coefficient of thermal expansion (×10-6/℃) [20~800℃] |

Thermal conductivity (W/m・k) |

Maximum allowable temperature (℃) |

|---|---|---|---|---|---|---|---|

| Sialon | 3.2 | 750~950 | 290 | 710 | 3.0 | 17 | 1,250 |

| Super Sialon | 3.2 | 800~1050 | 300 | 750~1000 | 3.0 | 65 | 1,250 |

Sialon and Super Sialon are used primarily for the production of parts that come into contact with molten aluminum.

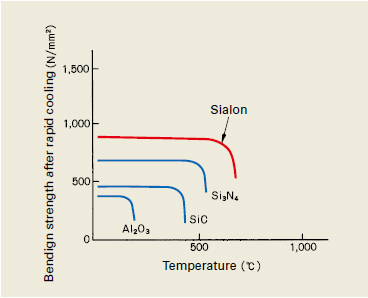

The characteristics of Sialon are given below in comparison with those of structural ceramics.

Figure 7: High-temperature strength

Figure 8: Thermal shock resistance

The data in our report do not constitute any kind of warranty or guarantee.

Roll Business Unit

ABOUT US

Leading sustainability by high performance

768,6

billion

18,877