Corrosion and hydrogen resistant martensitic stainless steels ACD™602,ACD™627

Product Catalog Download

Click here to download the product catalog

Contact

We propose a method to use materials tailored to your company.

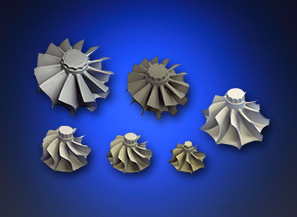

ACD™602 and ACD™627 obtain high surface hardness and corrosion resistance by nitriding-quenching. They keep their ductility even when exposed to high-pressure hydrogen. Such characteristics contribute to extend the life of ICE parts compared with common martensitic stainless steels.

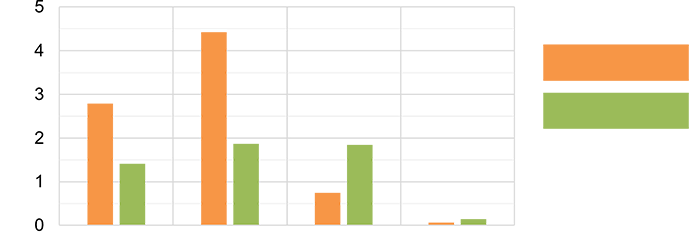

Corrosion resistance

- 5% CH2O2 : ACD627 shows 1/20 of corrosion rate compared with SUS420J2.

- pH1.5 H2SO4 : ACD627 shows 1/9 of corrosion rate compared with SUS420J2.

Corrosion rate (mg/h/cm2)

SUS420J2

SUS440C

ACD602

ACD627

5%CH2O2-24h

pH1.5 H2SO4-5h

Temperature : 50℃

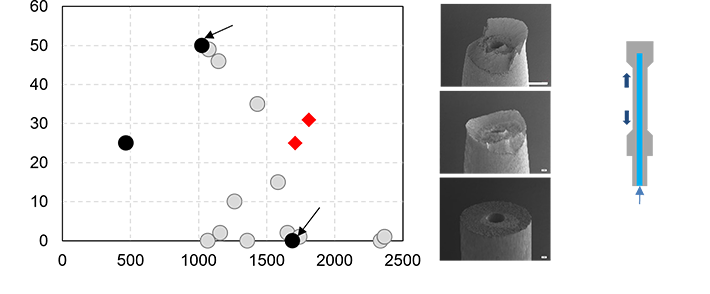

Resistance to hydrogen embrittlement

- ACD602 and ACD627 achieve both high tensile strength and good ductility in 10MPa of hydrogen.

- ACD602 exhibits high hydrogen resistance with 1800MPa of tensile strength and more than 30% of RA.

Reduction of area in H2 [%]

Tensile strength in H2 [MPa]

A286

FCD400

ACD602

ACD627

SUS440C

ACD602

RA: 31%

1mm

ACD627

RA: 25%

SUS440C

RA: 0%

Specimen

Tensile

H2 gas(10MPa)

Strain rate:5×10-5 (/s)

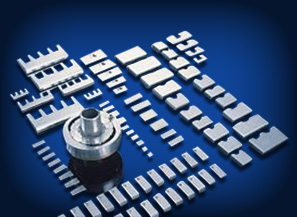

ApplicationsFuel injector (biofuel, e-fuel, hydrogen, etc.)

The characteristic values, photographs, charts, rankings, evaluations, etc. shown in this catalog are representative values based on our test data and do not guarantee the quality of the products. The information in this catalog is subject to change without notice.

Product Catalog Download

Click here to download the product catalog

Contact

We propose a method to use materials tailored to your company.

ABOUT US

Leading sustainability by high performance

768,6

billion

18,877