Metal Injection Molding (MIM) Cobalt Optical Communications Parts

We propose a method to use materials tailored to your company.

Overview

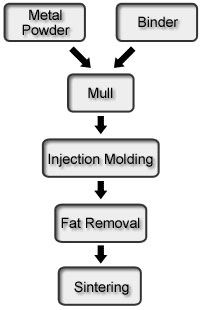

Figure 1: MIM Process Flowchart

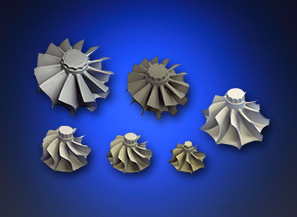

Currently, around the world efforts are being made to complete the fiber optic network. Accompanying this development, there has been a surge in demand for fiber-optic related products made from cobalt materials offering low thermal expansion. In particular, the complex-shaped packages have produced a high demand for low-cost, metal-powder injection molded products over conventional machine-assembled items. Our products have been created drawing on the Company's nearly 10-year track record with MIM technology. The MIM process, as shown in the flowchart appearing in Figure 1, is a manufacturing process for mass-producing complicated three-dimensional objects in near-net shapes.

Features

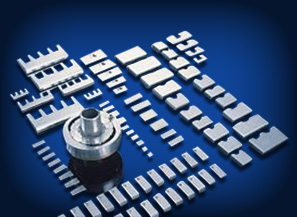

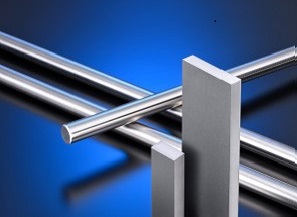

Figure 2: Samples of MIM Cobalt Optical Communications Parts

1. Molds and Dimensional Precision

Compared with conventional machining products, our products are low-cost, and, as Figure 2 shows, enable the production of complicated three-dimensional forms of near-net shaped sintered bodies. Furthermore, the dimensional precision is ±0.5

2.Special Features

(1) Low Thermal Expansion

With almost the same thermal expansion coefficient as molten manufacturing materials, it is ideal as an adhesive (See Chart 1.).

| Chart 1: Thermal Expansion Coefficient | ||

|---|---|---|

| 30~400℃ | 30~800℃ | |

| MIM sintered items | 4.20~4.80 | 9.60~10.20 |

| Molten manufacturing materials(ASTM F15) | 4.60~5.20 | (10.4) |

(2) Highly Airtight

The relative density exceeds 96%, which is an adequate degree of airtightness for packaging applications.

(3) High Purity

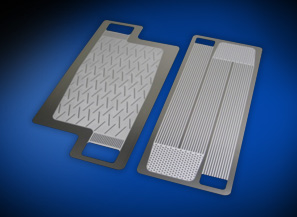

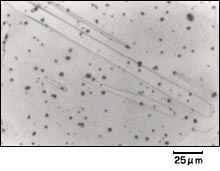

Due to its high density, it has few holes, as seen below (Figure 3), and is well-suited to metal plating.

Industrial Materials Dept.

ABOUT US

Leading sustainability by high performance

1,033.2

billion

21,456