New Contact Wire “GT-SNNS170” Developed

for Installation on the Seto-Ohashi Line of JR Shikoku

Proterial, Ltd.

Proterial, Ltd. (“Proterial”) developed the new contact wire “GT-SNNS170” with a longer life and improved ease of management and maintenance. The product was installed on one of the sections of the Seto-Ohashi Line of the Shikoku Railway Company (“JR Shikoku”). The Seto-Ohashi Line will be renovated to reduce the weight of all of the equipment installed on the line and extend its life. The equipment has traditionally used pure copper contact wire, which will be replaced by GT-SNNS170.

1. Overview

In general, the conventional railway lines use pure copper contact wire. Although the conductivity of pure copper contact wire is excellent, it is necessary to increase the strength and wear resistance of contact wire for smart railways (to enable automation and increase the efficiency of maintenance, for example) and necessary to extend the lifespan of the rails. Although the Seto-Ohashi Line currently uses pure copper contact wire, necessary parts of the renovation include extending the life of the rails and increasing the efficiency of maintenance because of the harsh environment specific to railways over the sea.

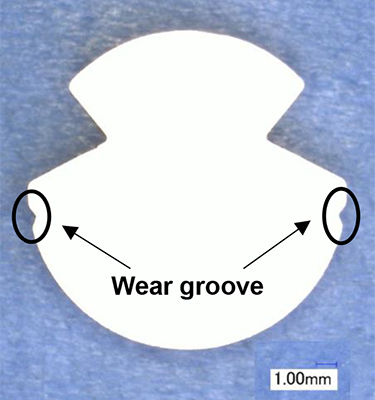

Proterial has developed the new GT-SNNS170 alloy contact wire with the addition of tin and indium. The product has a proof tensile load at least 20% higher than pure copper contact wire while keeping 80% or more of the electric conductivity. The structure of GT-SNNS170 is excellent for the visibility of wear status because of grooves created at the wear limit* in addition to its excellent antiwear properties.

GT-SNNS170 has been installed on one section of JR Shikoku's Seto-Ohashi Line. It is expected to extend the life of the rails and prolong the replacement cycle.

| Nominal cross sectional area (mm2) |

Model (Code number) |

Tensile load (kN) |

Elongation (%) |

Conductivity (%) |

|

|---|---|---|---|---|---|

| The newly developed product |

170 | GT-SNNS | 71.2 or more | 3.2 or more | 80 or more |

| Pure copper contact wire |

170 | GT | 57.8 or more | 3.4 or more | 97.5 or more |

2. Positive Effects

- 1Lower maintenance cost

It is expected to reduce personnel expenses and maintenance costs at the sites more subject to wear where the replacement cycle is shorter by extending the replacement cycle beyond what is possible with pure copper contact wire. - 2Increased maintenance efficiency

To increase maintenance efficiency, the contact wire facilitates people's understanding of wear conditions using grooves to enable wear management.

3. Installation on the Railway

GT-SNNS170 was installed on one section of the Seto-Ohashi line on January 16, 2023.

| Train line | Section | Overall Length |

|---|---|---|

| The Seto-Ohashi Line | Okayama - Seto Ohashi - Takamatsu | 71.8km |

Completely opened on April 10, 1988, in 2023 the Seto-Ohashi Line celebrates the 35th anniversary of its opening. GT-SNNS170 will be installed since a renovation is planned to reduce the load on the bridge members of the Seto-Ohashi Bridge through measures such as the reduction of the weight of the installed equipment.

- [Contact for press]

Corporate Communications Department, Proterial

https://www.proterial.com/e/contact/

- *By judging the amount that the wear of the grooves has advanced (the amount the ridges have been reduced) the mechanism enables the detection of the progress of wear which begins with the lower part and advances.