Amorphous alloy contributes to energy saving in power transformers

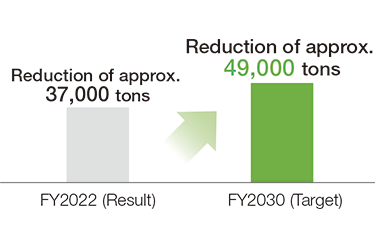

Power transformers lose power even when in standby mode. To solve that problem, since 2003 we have been providing Metglas™, an amorphous alloy that reduces standby power consumption to about one-third that in the case of conventional core materials (such as electromagnetic steel sheets) used for transformers.By providing core materials for amorphous transformers, the Proterial Group is aiming to contribute to reducing CO2 emissions* by approximately 50,000 tons per year (compared with the figure for conven-tional magnetic-steel transformers). In March 2020, we developed a new amorphous material called MaDC-A™, which will contribute to further improving transformer efficiency.

- *Based on shipment volume and difference in transformer energy loss, according to Indian standards. For the CO2 emission coefficient, we used the IEAʼs World CO2 Emissions from Fuel Combustion (2017).