Casting Technology Research Laboratory

Ever-advancing research and development

Research anticipating market needs

Focusing on casting technology for manufacturing cast iron products, the Casting Technology Research Laboratory is conducting research and development for producing fabricated materials and components enabling weight reduction and energy saving in the automobile industry. As a laboratory developing products anticipating market needs, we have promoted extensive research and development in close cooperation with our customers.

Relentless pursuit of weight reduction

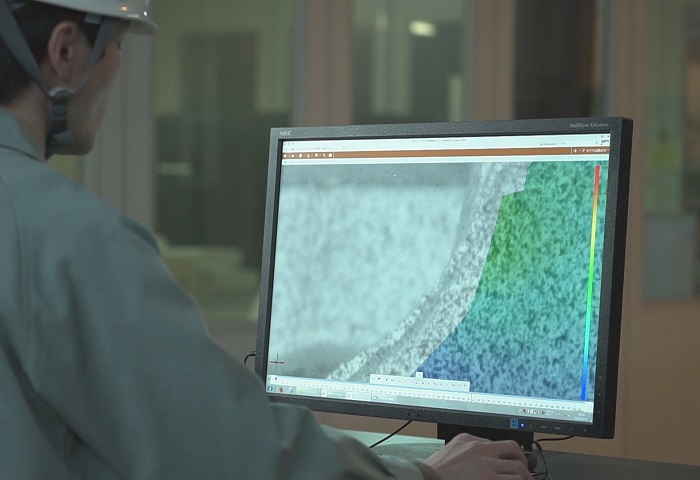

Casting is a technique for manufacturing products with complicated shapes by pouring high-temperature molten metal into molds made of sand or metal, and letting it cool and harden. Various applications require different properties including strength, toughness, heat resistance, productivity, as well as reduced weight. In addition to casting technology, our laboratory is working toward the development of materials with superior properties and the elucidation of the property development mechanism by electron microscopic analysis. Moreover, we are tackling the optimization of the casting process and the creation of light-weight structures using computer-aided engineering (CAE). Our efforts are also spent on the development of new materials including ceramics and composite materials, and their application in products.

Ahead of other foundries in Japan, the Casting Technology Research Laboratory will continue bringing next-generation fabricated materials to the market, contributing to reducing environmental load.