Applying Metal Additive Manufacturing Material ADMUSTER® C21P

(High Corrosion-Resistant Nickel-Based Alloy) to Mass Production

Hitachi Metals, Ltd.

Hitachi Metals, Ltd. ("Hitachi Metals") has been developing its ADMUSTER® series of metal additive manufacturing materials able to achieve high corrosion resistance and high strength for attention-getting metal additive manufacturing (metal 3D printing) that enables the creation of complex shapes, and has been expanding into various fields where the characteristics come into play. In particular, nickel-based alloy ADMUSTER® C21P in the ADMUSTER® series enables the creation of metal additive manufacturing products with 100 times or more*1 the corrosion resistance of SUS316L, a stainless steel. This higher reliability leads to the reduction of operation halt risks and lower frequency of part exchange as well as shorter part production lead times and the reduction of CO2 in fields that require high corrosion resistance, such as semiconductor manufacturing equipment; drug intermediate production; oil, gas, and other energy facilities; and chemical plants. As such, customer expectations for additive manufacturing are rising, and customers have started applying additive manufacturing to mass production.

1. Background

Additive manufacturing (3D printing), which will eliminate dies and assembly and enable the low-cost manufacture of complex-shaped products, is gaining the spotlight as a technique that is transforming conventional manufacturing. In addition, as of recently, it is being used for emergency alternative production in the event of supply chain disruptions caused by the COVID-19 pandemic and geopolitical risks, as well as a CO2 reduction measure. While attention is growing, we not only use existing materials, such as stainless steel, nickel-based alloy, and aluminum alloy, but are also actively developing new materials by taking advantage of additive manufacturing.

We have been developing additive manufacturing-specific materials mainly at the Global Research & Innovative Technology center (GRIT), a Hitachi Metals corporate research laboratory. Having rolled out the ADMUSTER® series of metal additive manufacturing materials, which includes those with high corrosion resistance and high strength, we are proposing the most appropriate material for each field where these characteristics are required.

2. Outline

Designed for additive manufacturing, ADMUSTER® C21P with high corrosion resistance is a powder material based on MAT21®, a nickel-based alloy with high corrosion resistance for wrought product, developed at Hitachi Metals' Okegawa Works. It currently has one of the highest PRE*2 numbers of all our metal additive manufacturing materials. Additive-manufactured products made from ADMUSTER® C21P have been confirmed to have the same corrosion resistance as MAT21® wrought material*3 along with excellent strength and hardness (see Tables 1 and 2). Test results show that compared to SUS316L, a stainless steel with relatively high corrosion resistance, as-built C21P (a just additive-manufactured test specimen) has one hundredth or less the corrosion speed (100 times or more the corrosion resistance).

Since chemical plants and semiconductor manufacturing plants use highly corrosive fluid, the corrosion resistance of the parts used for the equipment is important. Using parts with higher corrosion resistance makes it possible to improve reliability, resulting in reduced operation halt risk and lower frequency of part exchange. Furthermore, additive manufacturing eliminates die preparation and assembly processes and shortens the lead time for small lot production. Since these characteristics not only enable lower costs but also lead to the reduction of CO2 generated in the part production processes, customer expectations are rising, and customers have already started mass production of metal additive manufacturing parts made of ADMUSTER® C21P.

Hitachi Metals will contribute to the solution of customer issues and CO2 reduction by strengthening and expanding the lineup of the ADMUSTER® series into various fields requiring heat resistance, wear resistance, corrosion resistance, and high functionality.

| C21P as built |

C21P solution-treated |

C21P aging-treated*5 |

MAT21® wrought |

Alloy 22 wrought |

SUS316L wrought |

|

|---|---|---|---|---|---|---|

| PRE*2 | 82 | 70 | 26 | |||

| 1% HCl boiling | 0.01 | - | - | 0.01 | 0.13 | 24 |

| 2% HCl boiling | 0.01 | 0.01 | 0.01 | 0.05 | 1.72 | 51.2 |

| 5% HCl boiling | 1.6 | - | - | 1.15 | 7.95 | 199.3 |

| 30% HF room temp. | 0.06 | - | - | 0.08 | - | - |

| 10% H2SO4 boiling | 0.03 | 0.03 | 0.02 | 0.04 | 0.23 | 69.4 |

| Item | C21P as built |

C21P solution-treated |

C21P aging-treated*5 |

MAT21® wrought |

|---|---|---|---|---|

| 0.2% proof stress, MPa | 623-758 | 416-424 | 952 | 381 |

| Tensile strength, MPa | 885-1030 | 890-905 | 1440 | 812 |

| Hardness, HV10 | 288-323 | 206-209 | 428 | 180-200 |

- *1Our internal test data

- *2PRE: Pitting Resistance Equivalent number, an index of corrosion resistance. PRE = Cr + 3.3 (Mo + W/2) + 16N

- *3MAT21® forging and rolling material: Forged or rolled material made of high corrosion-resistant nickel-based alloy MAT21®

- *4The values are representative and not guaranteed.

- *5Aging treatment (Temp.; about 600℃, Duration; >30hour)

[Contact for customers]

AM Solution Center, Advanced Metals Division, Hitachi Metals, Ltd. Adachi, e-mail hajime.adachi.mz@hitachi-metals.com

[Contact for press]

Corporate Communications Dept., Hitachi Metals, Ltd. Minami, e-mail akio.minami.cq@hitachi-metals.com

Reference

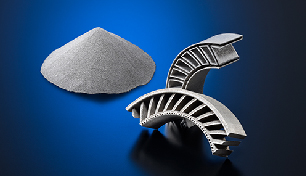

Main Products in the ADMUSTER® Series of Metal Additive Manufacturing Materials

Corrosion Resistant Materials

High Corrosion Resistant and

High Strength Alloy:

ADMUSTER® C00P

Multi-component (Co-Cr-Fe-Ni-Ti-Mo) alloys that are difficult to produce by the cast & wrought can be applied to structural parts by using additive manufacturing. Both high strength and corrosion resistance can be achieved by the multi-component nano-precipitate. Strength/hardness and ductility can be adjusted by tempering.

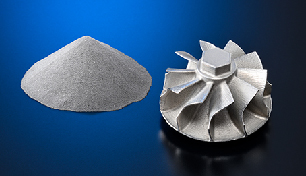

High Corrosion Resistant

Nickel-Based Alloy:

ADMUSTER® C21P

A nickel-based alloy, with high corrosion resistance and a good track record in a wide range of environments, is applied to metal 3D printing. It has the same corrosion resistance as wroght C21P, and realizes higher mechanical strength with 3D printing technology.

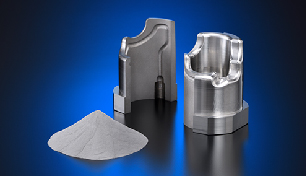

Hard Particle Dispersion

Strengthened Chromium-Based Alloy:

ADMUSTER® C574P

A hard particle dispersion strengthened alloy with excellent corrosion resistance and anti-sediment wear resistance. It achieves excellent corrosion resistance by an increased concentration of Cr.

High Strength Materials

Low Cobalt Maraging Steel

Powder for Additive Manufacturing:

ADMUSTER® W285P

ADMUSTER® W285P has the same strength as general maraging steel even with a cobalt content of 1% or less. (Exempted from control under class 2 controlled chemical substances in Japan) and is easy to handle for additive manufacturing.

High-Strength Maraging Steel

Powder for Additive Manufacturing:

ADMUSTER® W350P

ADMUSTER® W350P is a maraging steel characterized by its high hardness after aging annealing. It can be adjusted to a higher hardness than general 300ksi class steels.