Hitachi Metals Develops Ceramics Adsorption Filter

for Pretreatment of the SWRO Desalination System

February 12, 2019

Hitachi Metals, Ltd.

Hitachi Metals, Ltd. has developed a ceramics adsorption filter (CAF) as a pre-treatment technology for the seawater reverse osmosis (SWRO) desalination process in order to minimize fouling of RO membranes*1. A joint research study conducted by Hitachi Metals Ltd, Japan and the Nanyang Environment & Water Research Institute (NEWRI) at Nanyang Technological University, Singapore (NTU Singapore) have shown that with the addition of CAF in the pre-treatment stage prior to the RO stage, the rate of RO fouling was slower and hence the membrane cleaning frequency can be reduced. The findings have shown that the amount of biofilm attached on the RO membrane was significantly reduced. This is expected to reduce water production cost. Hitachi Metals will accelerate efforts toward commercial applications, and will expand the business in Singapore, which is the center of research of the water treatment technologies.

1. Background

Due to the population growth, economic growth, and climate change, water shortage has become a global issue. One of the Sustainable Development Goals (SDGs) promoted by the United Nations is to ensure the accessibility to clean water and improve in water quality and price.*2

Seawater desalination is one of the approaches to access to clean water. Currently, most seawater desalination systems use RO membranes. When seawater is desalinated using RO membranes, organic matter and other contaminants in the seawater may adhere to the membrane surface, a phenomenon known as fouling. The consequences of fouling include decrease in productivity, increase energy use, compromised water quality and shorten membrane life. All of these translate to higher water production cost. One of the key factors determining the degree of fouling on RO membrane is the RO feed water quality. As such, an effective pretreatment process is necessary prior to the RO system to ensure the fouling of RO membranes is minimized.

2. Overview

Against this backdrop, Hitachi Metals has developed a pre-treatment filter that aims to minimize fouling of RO membranes, known as the CAF. The CAF is a filter which has porous partition walls coated with an adsorbent material. Unlike the conventional filtration method which based on size exclusion to physically remove substances larger than the size of the pores, CAF utilizes a chemical action, namely adsorption, to selectively remove dissolved organic matter that is likely to be negatively charged, regardless of its size.

Hitachi Metals and NEWRI conducted parallel comparison on RO performances for seawater treated with UF*3 alone and the other seawater treated with UF followed by CAF system. The comparison studies have shown that the fouling rate of RO membranes can be reduced. The slower in fouling rate indicates that the RO cleaning frequency can be potentially reduced by half or more if CAF is used in between the UF membrane and RO membrane. This will likely cut down the operating cost of seawater desalination plants and improve the capacity utilization, resulting in lower water production cost.

Comment from Assistant Professor Chong Tzyy Haur, School of Civil and Environmental Engineering and Deputy Director, Singapore Membrane Technology Centre, Nanyang Environment and Water Research Institute, Nanyang Technological University

"Desalinated water is an important source of water. NEWRI is pleased to collaborate with Hitachi Metals to explore technologies that can improve the process efficiency which ultimately lead to lower cost of water production. We are excited about the commitment from HM to expand its business in Singapore."

Comment from Mr. Koji Sato, Vice President and Executive Officer and CTO of Hitachi Metals

"The global community faces a major issue in coping with environmental, energy, and resource problems to achieve sustainable growth. I am very pleased that we have made a step forward to solve the social issue of water shortage in collaboration with NEWRI. We remain committed to contributing to the future development of society by unleashing the potential of materials."

For inquiries from the press:

Corporate Communications, Hitachi Metals, Ltd.

hmcc.sa@hitachi-metals.com

[Supplementary information]

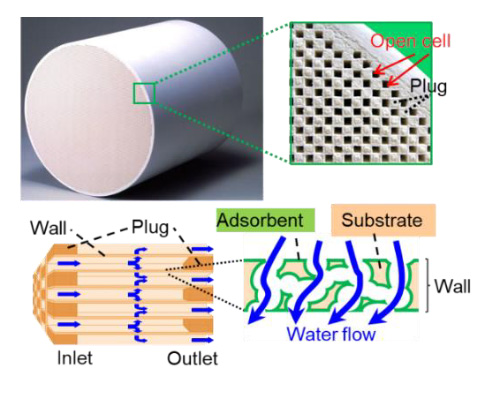

■ Overview of a CAF

| Material | Cordierite (base material) |

|---|---|

| Structure | A filter in which the inlet side and outlet side of the channel, arranged in a honeycomb structure, are alternately plugged |

| Performance | Capable of adsorbing and removing dissolved organic matter |

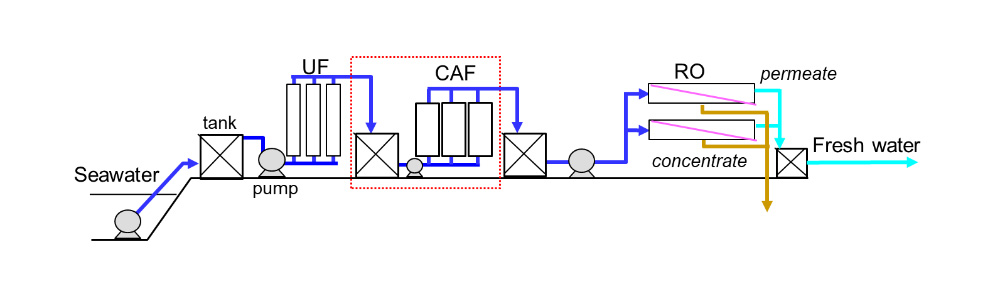

■ Process in a seawater desalination system using a CAF (conceptual image)

At some seawater desalination plants, UF membranes, which are highly effective for minimizing fouling of RO membranes, are used for pretreatment. In the demonstration experiment by NEWRI, to clarify the different substances removed by ultrafiltration membranes vs. a CAF, the latter was added downstream of an ultrafiltration membrane to verify the effectiveness of prevention of RO membrane fouling.

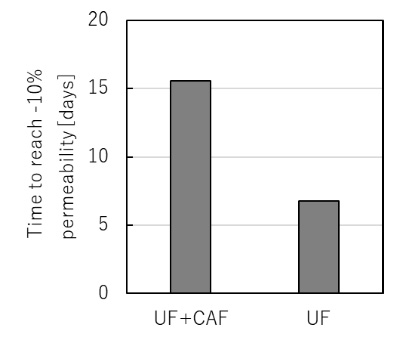

■ Effectiveness of introducing a CAF (based on the results of the demonstration experiments)

When permeability decreases due to the fouling of RO membranes, membranes are cleaned by chemicals to recover its permeability. The downtime to perform cleaning of the RO process is a factor that decreases the capacity utilization of seawater desalination equipment. The laboratory-scale demonstration experiment by NEWRI showed that with the implementation of CAF after UF treatment, the time required to reach the permeate flow rate drop of 10% is extended by 2.3 times compared to UF treatment alone.

Analysis from the autopsy with and without the use of CAF indicated the amount of biofilms*4 present on the RO membrane surface after a month of operation is less for the process with CAF. This is attributed to the ability of CAF to remove biodegradable dissolved organic matter in the UF permeate. The CAF is considered to reduce the speed of initial fouling of RO membranes with organic matter, thereby helping to prevent the formation of biofilms.

Profile of Nanyang Technological University (NTU)

A research-intensive public university, Nanyang Technological University, Singapore (NTU Singapore) has 33,000 undergraduate and postgraduate students in the Engineering, Business, Science, Humanities, Arts, & Social Sciences, and Graduate colleges. It also has a medical school, the Lee Kong Chian School of Medicine, set up jointly with Imperial College London.

NTU is also home to world-class autonomous institutes - the National Institute of Education, S Rajaratnam School of International Studies, Earth Observatory of Singapore, and Singapore Centre for Environmental Life Sciences Engineering - and various leading research centres such as the Nanyang Environment & Water Research Institute (NEWRI) and Energy Research Institute @ NTU (ERI@N).

Ranked 12th in the world, NTU has also been placed the world's top young university for the past five years. The University's main campus is frequently listed among the Top 15 most beautiful university campuses in the world and it has 57 Green Mark-certified (equivalent to LEED-certified) building projects comprising more than 230 buildings, of which 95% are certified Green Mark Platinum. Apart from its main campus, NTU also has a campus in Singapore's healthcare district.

For more information, visit www.ntu.edu.sg

Profile of Nanyang Environment & Water Research Institute (NEWRI)

Globally ranked among the top research and technology organization in the environment and water domain, the NEWRI ecosystem strives to take its lab-scale innovations to innovative engineered solutions for the water and environmental markets. With 'Research-Engineering-Deployment' (RED) as its guiding philosophy, NEWRI bridges deep research with cutting-edge innovation, robust engineering coupled with industry-level translation, to field applications, piloting and deployment at full scale in real life settings. Through industrial and CSR projects with commercial and social impact, NEWRI continuously strives to make a difference towards developing a true circular economy through efficient reuse innovations, and harnessing the value in waste.

The NEWRI ecosystem comprises five Centres of Excellence (AEBC, ECMC, EPMC, R3C, and SMTC), business development and a philanthropic initiative, an innovation cluster and a post-graduate education unit in environmental science and engineering, that form an inter-disciplinary and inter-institutional ecosystem to provide holistic environmental engineered solutions

Profile of Hitachi Metals, Ltd.

Hitachi Metals, Ltd., (TSE: 5486), headquartered in Tokyo, Japan, with consolidated revenue totaling 988 billion yen in fiscal 2017(ended March 31, 2018). The company manufactures and markets a diverse portfolio of specialty steel products, magnetic materials and applications, functional components and equipment, wires, cables, and related products.

For more information, visit https://www.hitachi-metals.co.jp/e/

[Terminology]

- *1An abbreviation for Reverse Osmosis. Two bodies of water of different salinity are placed adjacent to each other via a membrane that allows only water molecules to permeate; if the high salinity side is pressurized, the water molecules move to the low salinity side.

- *2One of the 17 goals. Goal 6: Ensure availability and sustainable management of water and sanitation for all

- *3An abbreviation for ultrafiltration. A filtration membrane whose pore size is approximately 0.001 to 0.1 µm for removing fine particles, polymers, microorganisms, etc. in water.

- *4Membrane-like aggregate that consists of microorganisms and substances secreted by them. Familiar biofilms include sticky sludge in kitchen sinks, dental plaque, and film formed on the surface of stones in water, etc.