Hitachi Metals Neomaterial Develops Clad Terminal

for Lithium-ion Batteries (LIBs)

January 24, 2019

Hitachi Metals Neomaterial, Ltd.

Hitachi Metals Neomaterial, Ltd. ("Hitachi Metals Neomaterial") has developed a clad material created by processing an aluminum and copper (Al/Cu) clad material. The clad terminal will help improve the connection reliability of automotive lithium-ion batteries (LIBs) used under severe conditions, reduce assembly man-hours and lower LIB weight.

1. Background

Amid the trend towards enhanced environmental regulations in different countries with a view to reduce CO2 emissions, electric vehicles (EVs), plug-in hybrid vehicles (PHVs) and other electric vehicles are forecasted to rapidly become widespread. In view of their increased use, their range must be extended. Research and development efforts are underway to tackle the current challenges of raising the output of LIBs as a key component and reduce the weight of the overall vehicle.

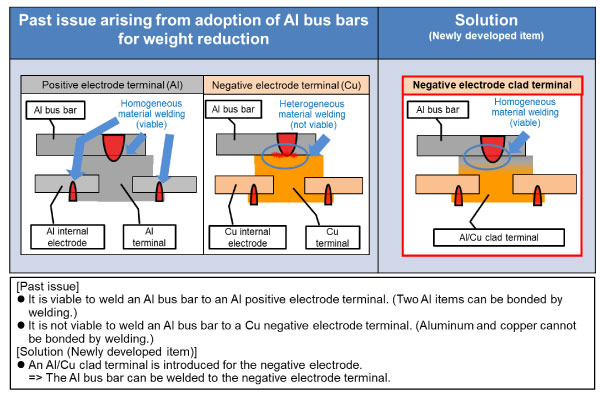

In the existing LIB module, multiple LIB cells are interconnected via copper (Cu) bus bars*1. Normally, LIB cells have positive electrode terminals made of aluminum (Al) and negative ones made of copper. Direct welding between an aluminum positive electrode terminal and a copper bus bar generates a fragile intermetallic compound on the joining interface, impeding connection reliability. Therefore, they are interconnected using bolts and nuts. In an environment where aluminum bus bars are increasingly adopted in pursuit of weight reduction, it is vital to ensure reliability in the joining part with the copper negative electrode terminal.

2. Overview

Hitachi Metals Neomaterial recently invented a clad terminal for LIBs. It is produced by processing an Al/Cu clad material as a response to the technological challenge regarding the reliability of the joining section.

The clad terminal is composed of an aluminum head and a copper base. When it is used in place of the conventional negative electrode terminal, it is possible to join two aluminum parts, namely the aluminum bus bar and the aluminum head of the clad terminal, by welding (refer to Supplementary Explanation). It achieves higher reliability of the joining section. The Al/Cu clad material used for clad terminals is prepared by connecting aluminum with copper through different processes, including a unique pressure welding*2 method, and by applying optimal heat treatment to facilitate inter-metal bonding. As a result, it has a very strong bond in the form of terminals.

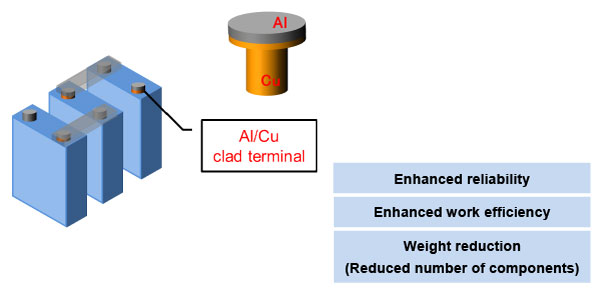

Hitachi Metals Neomaterial introduced these structural enhancement measures to develop the clad terminal leading to enhanced LIB connection reliability under severe vehicle operating conditions, fewer workload required than for the conventional assembly of multiple materials, and lower weight automotive batteries.

The Hitachi Metals Group will continue to broaden its product lineup including clad materials in an effort to enhance the performance of automotive and other components.

3. Production Facility

Hitachi Metals Neomaterial, Ltd. (Head Office: Suita, Osaka Prefecture, Japan)

4. Patent

Application pending

For inquiries from customers:

Specialty Steel Company, Hitachi Metals, Ltd.

For press inquiries from the press:

Corporate Communications Office, Hitachi Metals, Ltd.

hmcc.sa@hitachi-metals.com

◆Supplementary Explanation (Red area indicates welding portion.)

◆Application example: Prismatic cells

Notes

- *1A bus bar is a plate-shaped conductor without insulation coating. It is a type of wiring material.

- *2Pressure welding is a process in which homogeneous or heterogeneous metals are joined by applying strong pressure.