Hitachi Metals Neomaterial Announces

the Development of Clad Current Collector

for Large-Capacity Lithium-ion Batteries

January 23, 2017

Hitachi Metals Neomaterial, Ltd.

Hitachi Metals Neomaterial, Ltd. (hereinafter referred to as Hitachi Metals Neomaterial) is pleased to announce the successful development of clad current collector for large-capacity lithium-ion batteries. Batteries employing this current collector have achieved excellent characteristics according to public research institutes and battery manufacturers. Production of the product will commence around 2019.

1. Background

Lithium-ion batteries have been used in a wide range of products, such as mobile devices, hybrid cars, and electric cars, due to their advantages of high energy density, small size, and light weight; and demand for such batteries is expected to substantially grow in the future.

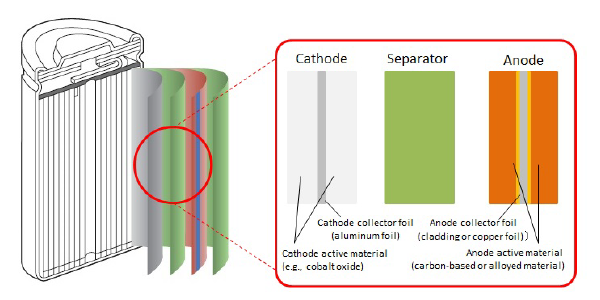

Lithium-ion batteries used in electric cars are desired to have a greater capacity that enables a longer cruising range. One method for increasing capacity is using alloyed materials such as Si (silicon), which has a larger gravimetric and volumetric capacities compared to conventional carbon-based materials, as the anode active material. On the other hand, alloyed materials are problematic in that they have larger changes in volume during charging and discharging compared to carbon-based materials, and thus, a large force will be applied to the current collector when charging and discharging are repeated many times. This causes the current collector to become crinkled, causing cracks in the active material layer and reducing the life of the lithium-ion battery. To prevent this, current collector with sufficient strength to withstand changes in volume during charging and discharging are desired.

2. Outline

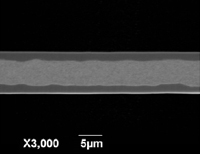

The clad current collector for large-capacity lithium-ion batteries developed by Hitachi Metals Neomaterial is a three-layer clad metal that uses Ni-Nb alloy with superior strength and rolling processability as the core material, and Cu (copper) with low electrical resistance as the surface material. Adding approximately 5% of Nb (niobium) to Ni (nickel) allows the clad metal to achieve a high tensile strength, while the addition of Cu simultaneously allows for low electrical resistance. In addition, in comparison to electrolytic copper foil and rolled copper foil that are commonly used as anode current collector foil, this clad current collector foil has a higher tensile strength, allowing it to withstand changes in volume that occur when an alloyed material is used as the anode active material, thereby contributing to achieving higher capacity lithium-ion batteries.

Hitachi Metals Neomaterial is committed to implementing growth strategies primarily based on the enhancement and expansion of the business of battery materials including clad metals, with a target of 36 billion yen in sales by FY2021.

| Clad foil (Developed product) |

Electrolytic copper foil |

Rolled foil | Stainless steel foil |

|

|---|---|---|---|---|

| Materials | Cu/Ni-Nb/Cu | Pure Cu | Cu alloy | Fe-Cr alloy |

| Tensile strength (MPa) | 880 | 300 to 450 | 400 to 550 | 1,000 to 1,400 |

| Electric resistivity (×10-8Ω・m) | 4.5 | 1.8 | 1.8 to 1.9 | 55 to 75 |

For inquiries from customers:

High-Grade Metals Company, Hitachi Metals, Ltd.

For inquiries from the press:

Corporate Communications, Hitachi Metals, Ltd.