Hitachi Metals Develops Low-Capacitance Micro Coaxial Cable

for Medical Devices

September 28, 2015

Hitachi Metals, Ltd.

Hitachi Metals, Ltd. has developed a new low-capacitance*1 micro coaxial cable for medical devices that uses fluorocarbon polymers in monofilament form for insulation. The outer diameter is approximately 14 percent smaller compared to our smallest-diameter conventional low-capacitance coaxial cable. The product is expected to provide better handling and higher-definition images in medical devices such as ultrasound diagnostic equipment and endoscopes.

1.Background

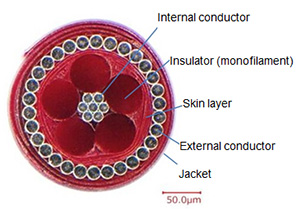

A coaxial cable is a set of wires composed of an internal conductor, insulator, external conductor and jacket. It offers high-transmission signal performance and superior noise resistance, and is used in a wide variety of applications including medical devices, mobile terminals and factory automation equipment. Particularly in terms of medical devices, coaxial cables need to be lighter in weight and smaller in diameter to reduce handling issues and effects on patients when inserted into the body.

In recent years, the improved performance of such medical devices as ultrasound diagnostic equipment and endoscopes has resulted in diagnostic images that are much higher in definition. Under the circumstances, the need for medical wires/cables of lower capacitance with better transmission performance and smaller diameters has been on the rise.

2.Overview

coaxial cable for medical devices

Our newly developed coaxial cable for medical applications meets both of the above requirements—lower capacitance and smaller wire diameter—through the use of monofilament fluorocarbon polymers as insulation. As opposed to the extruded foam fluorocarbon polymers used to insulate conventional cables, the monofilament fluorocarbon polymers in our new cable are stranded over the internal conductor. This gives the cable a relative permittivity*2 equivalent to a foamed insulator of ultra-fine diameter and light gauge, which was not possible using the conventional extrusion method.

■Features

(1)The outer diameter is approximately 14 percent lower compared to the conventional low-capacitance coaxial cable of the smallest diameter.

(2)The attenuation at 10 MHz is approximately 10 percent lower compared to the conventional cables of similar outer diameters with high capacitance.

3.Commercial Production

Scheduled to start in fiscal 2016

Production site: Hitachi Cable Fine Tech, Ltd. and Hitachi Cable (Suzhou) Co., Ltd.

4.Patent

Pending

For inquiries from customers:

Cable Materials Company, Hitachi Metals, Ltd.

For inquiries from the press:

Corporate Communications, Hitachi Metals, Ltd.

<Supplemental explanation>

■Comparisons of diameters and characteristics between our new product and conventional products

| Our New Product | Conventional Products | ||

|---|---|---|---|

| 48AWG*3 | 46AWG | 46AWG | |

| OD-coaxial cable | 0.215mm | 0.250mm | 0.195mm |

| OD-128 core cable | 3.8mm | 4.3mm | 3.5mm |

| Capacitance (at 1 kHz) | 70pF/m | 60pF/m | 120pF/m |

| Attenuation (at 10 MHz) | 1.30dB/m | 0.85dB/m | 1.45dB/m |

| Attenuation (at 50 MHz) | 1.80dB/m | 1.25dB/m | 2.35dB/m |

| ±90 deg. Bending (R = 2mm) | Five hundred thousand times ≦ | Five hundred thousand times ≦ | Five hundred thousand times ≦ |

- *1Capacitance refers to the volume of charge stored in an insulated conductor. In general, smaller capacitance per unit of length leads to better transmission performance.

- *2Relative permittivity is an index that indicates an electrical characteristic of an insulator. The more low-permittivity materials used, the greater the reduction in capacitance.

- *3AWG is the abbreviation for American wire gauge, and is used to specify the diameters of conductors.