Hitachi Metals Announces Development of Metal Powder

Cores New Product Crafted from Soft Magnetic Materials

September 19, 2014

Hitachi Metals, Ltd.

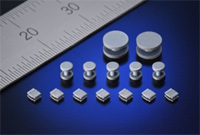

Hitachi Metals, Ltd. (head office: Minato-ku, Tokyo; chairman and chief executive officer, Kazuyuki Konishi; hereafter Hitachi Metals) is pleased to announce its development of "metal powder cores"—innovative new products comprised of soft magnetic materials—through the application of its powder metallurgy and powder-processing technologies. Delivering a superb combination of high performance and high reliability, these new products will contribute greatly to efforts to reduce the size of automobile electric components, mobile electronics and other cutting-edge devices as well as enhance their dependability.

1.Background

Hitachi Metals is a leader in the production and sales of soft ferrite, one of the soft magnetic materials used in the electrical circuits of automobile electric components, mobile electronics and other products. The company has earned stellar assessments for the outstanding and stable quality of its soft ferrite products, which many customers continue to adopt.

The recent quest for higher performance in automobile electric components, mobile electronics and other products has been accompanied by growing demands for electronic parts able to handle greater current levels. Along with greater space-saving requirements, there is a strong need to reduce the size of the high-density electronic parts in electrical circuits.

The insistence on smaller configurations has been particularly fierce in terms of inductors*1—components that take up a relatively large share of an electronic products space. At the same time, the need to strike a working balance between the capacity of inductors to handle higher currency loads and the shift to smaller dimensions has spawned a need to improve the magnetic characteristics, strength and other traits and physical properties of the materials used in magnetic cores— a component of inductors that heavily affect performance.

2.Outline

Newly developed with the use of soft magnetic materials, Hitachi Metals' unique metal powder cores are based on our powder metallurgy and powder-processing technologies. Compared to the soft ferrite option, not only does this new type of core deliver major improvements in saturation flux density, it also ensures stable magnetic characteristics across wide temperature ranges. Simultaneously, we have realized outstanding mechanical strength properties. Compared to other ferroalloy soft magnetic materials, the corrosion resistance*2 of these materials has also been elevated to an impressive level.

When used as cores for inductors or other components, metal powder cores are anticipated to be highly effective in further downsizing electric circuit boards mounted in automobiles, mobile electronics and other products. They are also expected to improve the operational stability and long-term reliability of such substrates.

Another key benefit of adding metal powder cores to our soft magnetic materials product line-up is the company's ability to address the expanding range of our customers' needs.

■Main Features of Metal Powder Cores

- 1High saturation flux density*3 for downsizing at high-current domains (minimum size = 2.0mm × 1.6mm), and major effectiveness in curbing declines in inductance*4 under conditions of high current flow. (Saturation flux density is approximately three times that of our current soft ferrite product line*5.)

- 2Stable magnetic characteristics in response to temperature changes, along with the capacity to address needs in high-temperature environments

- 3Outstanding mechanical strength that supports slimmer dimensions (maximum slimming to 0.8mm)

- 4High electrical resistivity for reducing overcurrent loss in high-frequency domains

- 5High anticorrosion performance that enables long-term reliability

3.Mass Production

- Scheduled launch

- Second half of 2014

- Production base

- Hitachi Ferrite Electronic, Ltd. (head office: Tottori City, Tottori Prefecture)

4.Sales Target

¥2.0 billion/year (FY2018 net sales)

For inquiries from customers:

Magnetic Materials Company, Hitachi Metals, Ltd.

Tel: +81-3-5765-4044

For inquiries from the press:

Corporate Communications Office, Hitachi Metals, Ltd.

hmcc.sa@hitachi-metals.com

<Supplementary Explanations>

- *1"Inductors" are key components used in electrical circuits in combination with resistors and condensers. Inductors are widely adopted to convert electrical energy into magnetic energy for storage and then release, and also handle voltage conversion, current smoothing and noise suppression.

- *2"Corrosion resistance" refers to the status of changes in magnetic characteristics and external appearance during shelf tests of a thousand hours or more performed under conditions of high temperature and high humidity (85°C/85RH%).

- *3"Saturation flux density" refers to the relative strength of magnetic force that materials can handle, and serves as a basic benchmark of magnetic materials performance. The degree of magnetization upon magnetizing materials is referred to as "magnetic flux density," with the move to larger values proportional to the downsizing of cores. Saturation flux density likewise indicates the top limit of magnetization when magnetizing materials.

- *4"Inductance" is the value used to express the ratio between the current flowing into the coils of coiled components and the magnetic flux occurring in coils into which the current is channeled.

- *5A comparison with Hitachi Metals' present soft ferrite product line: The main characteristics of our newly developed metal powder cores and the current soft ferrite versions are summarized below.

| Metal Powder Cores(newly developed) | Soft Ferrite Cores(present type) | |

| Saturation flux density | 1.5T | 0.4T |

| Magnetic permeability | 40 | 300 |

| Electrical resistivity | 1.2×104Ωm | 106Ωm |

| Curie temperature | Approx. 700℃ | Approx. 200℃ |

| Radial crushing strength | 200MPa | 120Mpa |

- *"Magnetic permeability" is one of the indicators used to evaluate soft magnetism, and expresses the relative ease of magnetization in reaction to externally applied magnetic fields.

- *"Curie temperature" refers to the temperature when a ferromagnetic substance changes into a paramagnetic substance, or when a ferroelectric substance changes into a paraelectric substance.

- *"Radial crushing strength" refers to the load level capable of causing breakage in loop-shaped cores upon compression.