Keio Line Introduces Proterial’s Durable Contact Wire

Proterial, Ltd.

The durable contact wire (the electrical wire for supplying electricity to railroad vehicles) manufactured by Proterial, Ltd. (hereafter “Proterial”) has been introduced on Keio Corporation’s Keio Line. This is the first time a private railroad company has used it. The product is designed to have longer service life than pure copper contact wire and it is easier to manage and maintain. Using the durable contact wire in a wider area is expected to help the Keio Line reduce its personnel and maintenance costs and increase maintenance efficiency.

1. Background

Contact wire is an important component of railroads. It is used to supply electricity to railroad vehicles via their pantographs. Today, private railroad companies including the Keio Line mainly use pure copper contact wire, prioritizing increased conductivity. In recent years, however, it has been necessary for these companies to manage the increasing price of copper and maintenance costs.

2. Outline

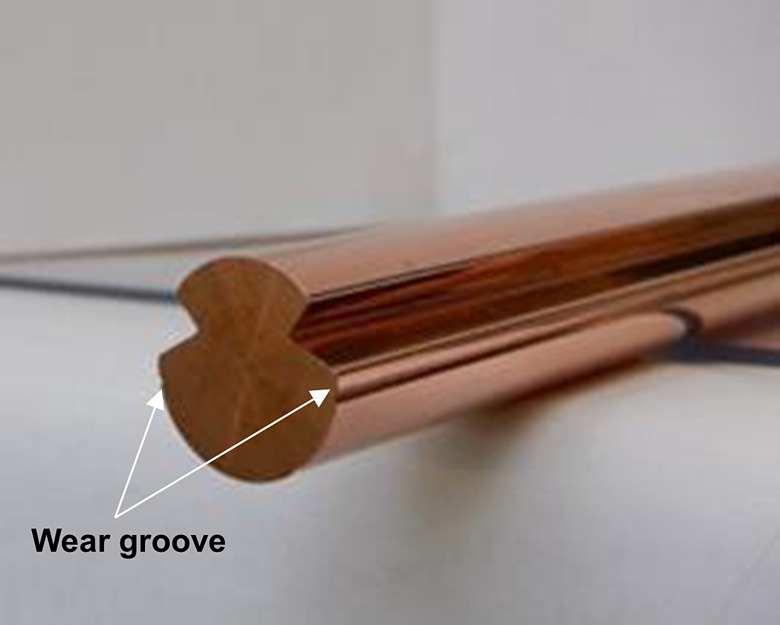

Increasing the tensile strength of contact wire can decrease its reference diameter for replacement. Increasing the contact wire’s wear resistance can extend the time before it reaches the reference diameter for replacement. By doing these things, it is possible to extend the service life of contact wire. By adding tin and indium to high-purity copper, Proterial has developed a high-strength alloy contact wire whose tensile load is at least 20% greater than pure copper contact wire and its wear resistance is also greater (SNN contact wire, winner of the 71st Okochi Memorial Technology Prize). The sides of the newly developed contact wire have wear grooves* on the wear limit positions to increase maintenance efficiency. This makes it easy to visually check the progression of wear and is expected to increase maintenance efficiency.

Proterial has proposed SNN contact wire with wear grooves (GT-SNNSK110) for railroad companies based on its expected ability to extend the service life and replacement cycle and increase the efficiency of maintenance work.

As a result, the Keio Line has become the first private railroad company to introduce the contact wire (GT-SNNSK110). Using the durable contact wire in a wider area is expected to help the Keio Line reduce its personnel and maintenance costs and increase maintenance efficiency.

- *Wear begins in the lower part of the contact wire, and the remaining distance to the groove is used to determine the progress of wear. As wear progresses diagonally in curved sections and similar areas, wear grooves are cut on both sides to make it possible to visually check the progression of wear on any of the wire’s sides.

| Nominal cross sectional area (mm2) |

Symbol | Tensile load (kN) |

Elongation (%) |

Conductivity (%) |

|

|---|---|---|---|---|---|

| New contact wire | 110 | GT-SNNSK | 47.3 or more | 2.8 or more | 80.0 or more |

| Pure copper contact wire | 110 | GT | 38.25 or more | 3.0 or more | 97.5 or more |

3. Installation on the railway

GT-SNNSK110 was installed in some sections of the following train line from August 21 to 29, 2024.

| Train line: | Keio Line |

|---|---|

| Section: | Chofu - Nishi-chofu |

| Chitose-karasuyama - Sengawa |

4. Impact on Keio Corporation

- 1Cost reductions

Extending the replacement cycle beyond what is possible with the existing pure copper contact wire can be expected to reduce personnel and maintenance costs in places that are more subject to wear and the replacement cycle is shorter. - 2Increased maintenance efficiency

Using the wear grooves to easily detect the wear of the contact wire increases maintenance efficiency.

5. Comment from Keio Corporation

Today, Keio Corporation is facing a labor shortage in its technical workplaces because of difficulties in recruiting which stem from the decrease in the working-age population, the aging of the population and the declining birthrate, and an increase in the turnover rate due to the booming career-change market and other reasons. Additionally, the working population tends to shy away from late-night work which is unique to the railroad business.

Against this backdrop, Keio Corporation has decided to introduce GT-SNNSK110 high-strength alloy contact wire with the goal of reducing its maintenance workload and costs. Keio is the first private railroad company to introduce it.

Going forward, Keio Corporation will continue to be committed to introducing the latest technologies that will help aggressively solve human resource issues.

- Media Inquiries: Corporate Communications Dept.

https://www.cntct.proterial.com/contact/publish/inquiry_eng?g=01&c=001-01 - Customer Inquiries:

https://www.cntct.proterial.com/contact/publish/inquiry_eng?g=01&c=014