CALISMAT™, a technology for manufacturing CAM for LIBs developed by Proterial, is estimated by FEV to reduce CO2 emissions by 36%

Proterial, Ltd.

FEV Consulting GmbH

CALISMAT™, a technology for manufacturing cathode active materials (“CAM”) for lithium-ion batteries (“LIB[s]”) that was developed by Proterial, Ltd. (“Proterial”), contributes to solving environmental issues faced by the battery industry. An estimation by FEV Consulting GmbH (“FEV”) has found that CALISMAT™ makes it possible to reduce CO2 emissions by 36% compared to a conventional manufacturing method at a cost that is the same or lower. By providing CALISMAT™ to the battery industry as a decarbonization solution, Proterial will contribute to the enhancement of the environmental value of LIBs over their product lifecycle.

1.Background

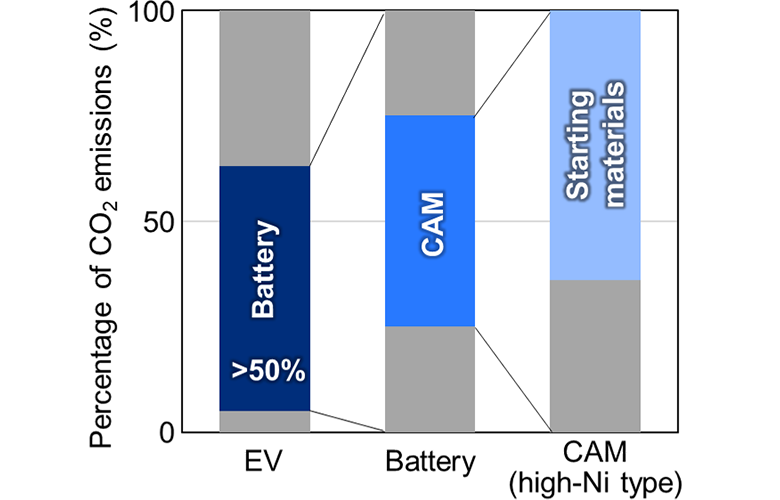

The demand for electric vehicles (EVs) is growing rapidly towards the realization of a decarbonized society, and LIBs are also attracting attention as an important component of EVs. However, the processes of manufacturing LIBs significantly impact the environment, with the CO2 emissions from these processes accounting for more than 50% of the total emissions from EV manufacturing. In the LIB-manufacturing processes, the percentage of CO2 emissions that are due to the CAM and their starting materials*1 are especially high (Figure 1). This was a major issue. In addition, sulfuric acid waste (Na2SO4) is emitted in the process of manufacturing CAM, and a large amount of water is needed to treat the waste, which was also an issue.

Proterial developed the CALISMAT™ technology for manufacturing CAM which solves these environmental issues faced by the battery industry and announced it in May 2023 (Figure 2 and 3). Proterial is committed to helping enhance the environmental value of LIBs by providing this technology to the battery industry as a decarbonization solution. To further accelerate this initiative, Proterial quantitatively evaluated the environmental value of CALISMAT™ with the cooperation of FEV, a global strategy consultancy and engineering service provider in the automotive industry.

2.CALISMAT™, a technology for manufacturing cathode active materials

Proterial has developed CALISMAT™, a technology for manufacturing CAM for LIBs without producing a precursor by using a solid-phase reaction method*3 based on powder metallurgy technology (Figure 3). Using CALISMAT™ provides benefits, including the availability of starting material options other than nickel sulfate (NiSO4), such as metallic nickel (Ni) and nickel oxide (NiO) and eliminates the need for waste treatment of sodium sulfate (Na2SO4).

3.Estimate of the value of using CALISMAT™

FEV has estimated the environmental value and cost-reduction effects of the conventional co-precipitation method and CALISMAT™ based on the knowledge it has accumulated through providing strategy consulting and engineering services to automotive and battery manufacturers in key regions, including Europe, United States, China, Japan, South Korea and India. The following estimates were obtained, verifying that CALISMAT™ has an environmental impact-reducing effect.

- The carbon footprint of NMC CAM manufacturing is reduced by 36%

- Water consumption is reduced by more than 85%, which simultaneously reduces the effort required for wastewater treatment

- CAM costs, which account for around 40% of total battery cell costs, are reduced by 6%*4

The results of this verification will be exhibited at Hannover Messe 2025 (venue: Messegelände Hannover), which will be held in Germany from March 31 to April 4, 2025.

- Media Inquiries: Corporate Communications Dept.

https://www.cntct.proterial.com/contact/publish/inquiry_eng?g=01&c=001-01 - Customer Inquiries:

https://www.proterial.com/e/contact/

- *1Raw material used as the starting point necessary for the initial chemical reaction in the generation of chemicals for cathode materials.

- *2Prepared by Proterial based on IEA Global EV Outlook 2020, Sustainable Materials and Technologies 32 (2022) e00415.

- *3A manufacturing method based on powder metallurgy technology, in which a cathode material is synthesized by pulverizing, mixing, granulating, and sintering a starting material powder without dissolving it in water.

- *4Based on starting materials prices from early 2025

CALISMAT is a trademark of Proterial, Ltd.

| Headquarters: | Neuenhofstr. 181, 52078 Aachen, Germany |

|---|---|

| Business description: | FEV Group is a globally leading engineering provider in the automotive industry and internationally recognized leader of innovation across different sectors and industries. FEV Consulting, founded in 2011, is the management consulting arm of FEV Group and acts as a bridge between strategy and technology. The company combines many years of experience in top management consulting with deep product understanding and technical know-how. As part of the mobility and energy ecosystem, it integrates different industry-specific capabilities. This enables FEV Consulting to create sustainable product and strategy solutions for some of the most pressing and complex issues facing today’s enterprises. Core services range from development of business, growth and innovation strategies, to technology concept studies, production planning and cost optimization of products and processes. FEV Consulting currently has around 150 employees serving a global client base out of offices in eight different countries – Germany, the United States, Spain, France, UAE, Saudi Arabia, China and Japan. |

| Representative: | Alexander Nase, Global Managing Director |

| Established: | 2011 |