Developing HBZ-B40 EDM Wire with Thick 0.4 Millimeter Diameter —Contributing to the Improvement of Cutting Speed and Surface Accuracy*1 in Wire Electrical Discharge Machining—

Proterial, Ltd.

Proterial, Ltd. (“Proterial”) has developed the HBZ-B40 series of thick electrical discharge machining wire (“EDM wire”) with a 0.4 mm diameter designed to increase the cutting speed of electrical discharge machining and the surface accuracy of work materials. This wire will fulfill needs regarding the continued decrease of machining time as needs for the wire electrical discharge machining of large components such as large dies for automobiles, airplanes, electricity generating turbine components and metal additive manufacturing are increasing.

The HBZ-B40 series of products will be exhibited at the Makino Milling Machine Co., Ltd. (“Makino”) booth at the 32nd Japan International Machine Tool Fair (“JIMTOF2024”) to be held at Tokyo Big Sight beginning on and Tuesday, November 5, 2024. Makino is a partner in the development of the HBZ-B40 series of products.

1.Background

Recently, work materials in diemachining and componentmachining processes have becomelarger and thicker due to increaseddemand for xEVs and airplanesand initiatives to improveproductivity. These changes haveled to relative increases inmachining time and the degree ofdifficulty of machining, which inturn has increased demand forthick EDM wire that improvesboth the cutting speed of wireelectrical discharge machining and its surface accuracy.

Today, the commonly used EDM wire diameters range from 0.1 to 0.3 mm in Japan due to processingmachinery restrictions. Wire with a 0.3 mm diameter, which had been previously regarded as thick, had abreaking load which decreased the efficiency of machining because heat would break the wire when a largecurrent was applied during the machining of large work materials or when attempting to shorten machiningtime. Additionally, it has recently become necessary to improve the surface accuracy of finish machiningprocesses (reducing surface roughness). Therefore, electrical discharge performance must be improved, andwire diameter must be increased to shorten machining time and improve surface accuracy at the same time.

2.Outline

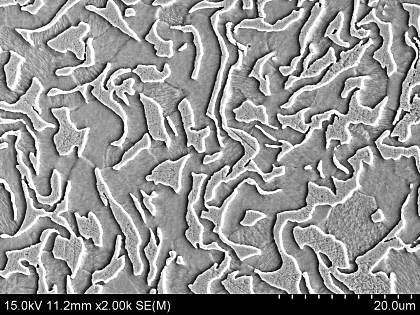

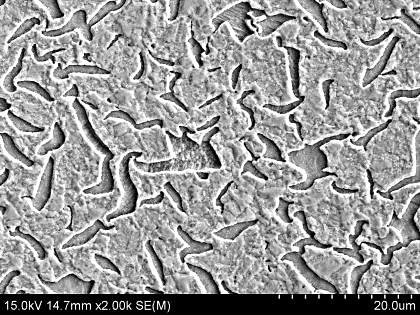

With many years of experience with EDM wire, Proterial has been providing HBZ-U high-zinc brass wire (60% Cu, 40% Zn), which Proterial developed before other manufacturers. Refining this technology, Proterial has developed HBZ-B40 Series high-zinc brass (57% Cu, 43% Zn ) which has even greater zinc content and a 0.4 mm diameter.

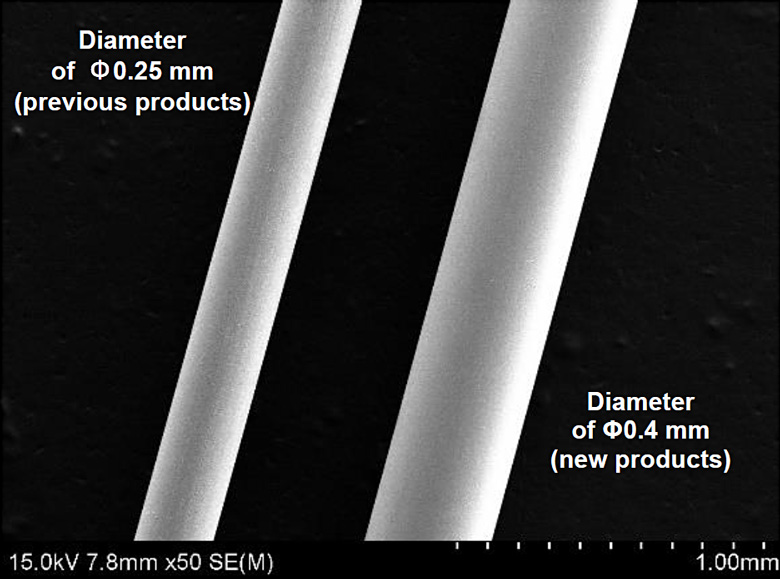

Wire with a diameter of 0.4 mm has almost double the breaking load of the commonly used 0.25 mm wire. The increased zinc content improves electrical discharge efficiency and electrical discharge performance. As a result, the new series of products makes it possible to achieve cutting speeds 10% faster than when using the previous products with the same 0.4 mm diameter, and to achieve high-precision machining with an approximately 7% reduction in the surface roughness of the worked surface and improved surface accuracy (in a demonstration experiment in cooperation with Makino).

| Specifications/product name | HBZ-B (New Products) | HBZ-U (Previous Products) |

|---|---|---|

| Wire diameter (mm) | 0.4 | 0.4 |

| Wire diameter tolerance (mm) | +0, -0.002 | +0, -0.002 |

| Composition (%) | Cu57/Zn43 | Cu60/Zn40 |

| Base metal structure*2 | Phase α + Phase β (more Phase β)

|

Phase α + Phase β

|

Demonstration Experiment (in cooperation with Makino)

Proterial will promote the use of HBZ-B40 series products in Japan and abroad in cooperation with Makino which sells Wire EDM that can use these products. HBZ-B40 series products will be exhibited at the Makino booth at JIMTOF2024 which will be held at Tokyo Big Sight beginning on Tuesday, November 5, 2024.

HBZ-B40 series products (the photo provided by Makino)

(HBZ-B40 is installed outside the Wire EDM)

3.Patents

Applications already filed

- Media Inquiries: Corporate Communications Dept.

Web inquiry form

- *1Degree of specularity and smoothness of the surface of a finished material that is molded using a die

- *2Phase α is flexible and easy to machine while phase β is hard and difficult to machine. If the zinc content is higher, the phase β ratio increases whereas electrical discharge performance is excellent and it is difficult to manufacture EDM wire. Therefore, advanced texture control technology and wire drawing processing technology are necessary.

- *3General index for defining surface roughness and standard based on the maximum measured values in JIS B 0601:2001.