Proterial Develops Magnetic Sheet for EV Wireless Charging Systems and MS-HiQ Series Magnetic Sheet Panels

Proterial, Ltd.

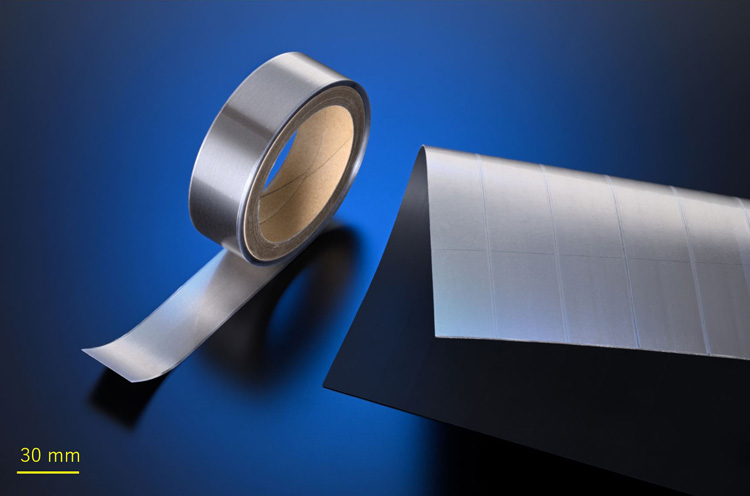

Proterial Ltd. has developed a magnetic sheet for electric vehicle (EV) wireless charging systems made of nanocrystalline soft magnetic material FINEMET® and the MS-HiQ Series*1 of magnetic sheet panels. The sheet will help improve efficiency and reduce the size and weight of wireless charging systems that will be increasingly introduced to EVs.

1.Background

Wireless charging has an advantage in that no power cord is required for charging. It initially found application with cardiac pacemakers and other medical equipment, and entered widespread use after it was introduced to smartphones. Lately, wireless charging has been attracting attention as a technology for supplying power to EVs. In 2020, the SAE J2954 standard for wireless power transfer for electric vehicles was published. It envisioned that the system would be used in parking facilities. Full-scale studies towards practical application are now underway. However, wireless charging systems have a drawback in that they are not as efficient as wired charging systems.

Enhancing the efficiency of wireless charging systems requires a coil composition with its quality (Q) factor reciprocal to the loss factor. This means that the loss is smaller when the Q factor is larger. For this purpose, it is effective to place a magnetic sheet on the back of the coil (or on the back of the wireless charging unit), as illustrated in Figure 1. In this configuration, the sheet acts as a shield*2 and also as a back yoke*3. Cellphones need thin magnetic sheets with a high Q factor. Proterial's FINEMET® has outstanding characteristics, which have given it a large market share. While wireless charging systems for cellphones have a power capacity of 20 W or less, those for EVs have a very large power capacity of 3 kW to 11 kW. It is now common to develop a technology of increasing the size and thickness with the use of ferrite, a magnetic ceramic, for magnetic sheets.

Proterial believed that the characteristics of the FINEMET® would also be useful to automotive applications and embarked on efforts to develop magnetic sheets for EV wireless charging systems.

2.Outline

Proterial has recently developed two original technologies explained below for heightening the quality factor for wireless charging systems.

- 1At the time of heat treatment of FINEMET ribbons*4 as constituents of a magnetic sheet, magnetic permeability control is performed while tensile strength is applied to the ribbons in their longitudinal directions to give them anisotropy. A wireless charging system equipped with magnetic sheets formed using the ribbons exhibits an improved Q factor.

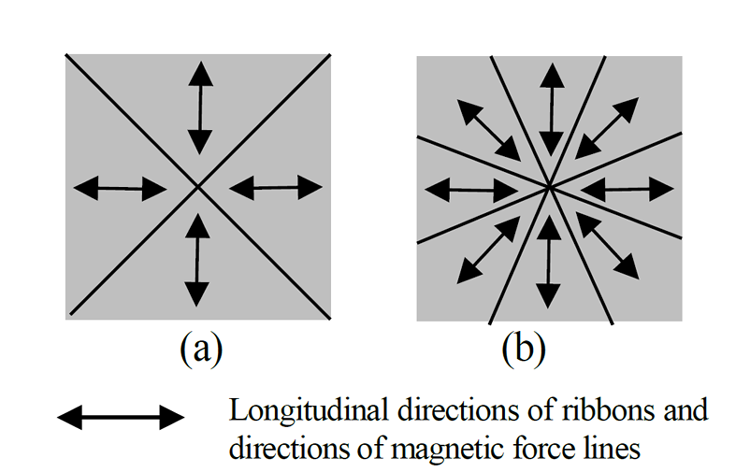

- 2The MS-HiQ magnetic sheet created by the technology described in (1) above is cut. A magnetic sheet panel is then formed by placing the cut pieces in a radial pattern to ensure that the longitudinal directions of the ribbons are identical with the directions of magnetic force lines, as portrayed in Figure 2. A wireless charging system with this panel exhibits a higher Q factor.

For producing a Q factor equivalent to that of a wireless charging system with ferrite on the back of the coil, a magnetic sheet panel consisting of four MS-HiQ elements, as seen in Figure 2(a), requires a thickness that is about half that of the aforesaid ferrite, and a magnetic sheet panel comprising eight MS-HiQ elements, as depicted in Figure 2(b), requires a thickness of around one third that of the ferrite. The experiment confirmed*5 that massive thickness and weight reduction could be achieved with this method.

After being introduced to EV wireless charging systems, the magnetic sheet and the MS-HiQ Series of magnetic sheet panels recently developed are expected to help increase efficiency and reduce the size and weight of such systems, encouraging the increasing take-up of the systems and EVs themselves.

End

- *1Series: A group of models that differ in terms of the number of ribbon layers, external dimension, double-side tapes and other specifications to choose from to ensure that the product is applicable to various purposes.

- *2Shield: A function to block electromagnetic noises from coming in to prevent them from having an adverse impact on the magnetic field or flux.

- *3Back yoke: A function that prevents a magnetic field or flux from dispersing.

- *4Ribbon: A single foil with a small thickness and a large width.

- *5According to the test performed by Proterial. Test conditions: An FM sheet sized 60 mm x 60 mm and a coil (Ls = 3.5μH, Rs = 28 mΩ@85kHz/10mA, Φ50 mm)

- Media Inquiries: Corporate Communications Dept.

https://www.cntct.proterial.com/contact/publish/inquiry_eng?g=01&c=001-01 - Customer Inquiries:Power Electronics Materials Business Unit

https://www.cntct.proterial.com/contact/publish/inquiry_eng?g=01&c=010

FINEMET are registered trademarks of Proterial, Ltd.