D2Materi™, a Materials Informatics Platform,

Applied to Wire Coating Material Development

Proterial, Ltd.

Proterial, Ltd. (hereinafter referred to as “Proterial”) has successfully applied D2Materi™ (hereinafter referred to as “D2Materi”), its proprietary Materials Informatics (hereinafter referred to as “MI”) platform, to the development of materials for wire coating materials. We have also used D2Materi in developing coating materials for wires used in actual rolling stock, and have verified that it can greatly shorten the time required to develop formulations of coating materials.

1. Background

MI is a technology for improving the efficiency of materials development with the use of informatics (information science) such as statistical analysis and machine learning. We expect that the use of MI will enable us to predict optimal combinations of materials with a high degree of accuracy. Based on microstructure and composition control technologies as well as academic knowledge that we have accumulated to date at Proterial, our materials informatics platform, D2Materi, enables designers to carry out designs by deriving correlations between, and laws and characteristics associated with performance and composition/processes.

As for electric wires, one of our main products, the characteristics of their coating material are a major factor that determines their performance. Characteristics, such as good insulation despite thinness, suppleness and durability, are achieved through various combinations of different polymers*1 and fillers*2. In the past, development relied on trial and error with a large number of combinations and numerous tests. To improve development efficiency, we enabled D2Materi to handle complex conditions that come with combining polymers (which are organic) with fillers (which are inorganic) in numerous combinations, and eventually applied D2Materi to the development of coating materials for wires used in rolling stock, which requires a high level of reliability.

2. Overview

(1) Application of D2Materi to wire coating materials

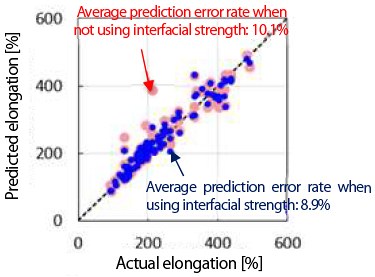

This shows that the error rate vis-a-vis actual physical properties is about 10%. We have verified that by adding a parameter corresponding to interfacial strength, the average prediction error rate improved from 10.1% to 8.9%.

By applying D2Materi in the development of wire coating materials, Proterial is now able to predict with high accuracy the formulation of polymers and fillers that deliver target characteristics.

In applying D2Materi to wire coating materials, we defined the weight of polymers and fillers as the explanatory variables*3, and the required characteristics as the target variables*4, and have also added data predicted to have an affect on material characteristics, such as parameters that correspond to the interfacial strength*5 of polymers and fillers, to build a unique model for predicting physical properties. The physical properties predicted using this model were found to be highly accurate, with an error rate of about 10% vis-a-vis actual physical properties.

(2) Using D2Materi to develop wire coating materials for wires used in rolling stock

In the development of coating materials for wires used in actual rolling stock, formulations being considered consisting of exhaustive combinations of different polymers and fillers were entered in D2Materi to obtain the predicted values of different physical properties. After selecting 20 types of formulations with excellent predicted properties, prototypes were made and verification experiments were conducted, which confirmed that good properties could be obtained. While it previously took about a year to obtain the optimal formulation, development using D2Materi was completed in less than three months, greatly improving the speed of formulation development.

Going forward, Proterial will accelerate development by applying D2Materi to advanced materials other than wire coating materials, and contribute to solving social issues such as fuel efficiency, energy conservation, and decarbonization.

We are scheduled to present this information at the 32nd Polymer Materials Forum hosted by the Society of Polymer Science, Japan, to be held at the Nagoya Congress Center from November 30 to December 1, 2023.

- [Media inquiries]

Corporate Corporate Communications Dept., Proterial

https://www.proterial.com/e/contact/

D2Materi is a trademark of Proterial, Ltd.

- *1Polymer: A high-molecular weight compound formed by combining a number of monomers

- *2Filler: Material added to resin for the purpose of improving its physical and other properties, etc.

- *3Explanatory variable: Data that influences the desired value

- *4Target variable: Target data to be predicted

- *5Interfacial strength: Strength of the interface between materials when dissimilar materials are composited