Silicone Sheath with Superior Sliding Properties

and its Application Product Received

the Minister of Education, Culture, Sports, Science and Technology

Award at the Kanto Region Invention Honors for Fiscal Year 2023

Proterial, Ltd.

Proterial, Ltd. (hereinafter “Proterial”) has been awarded the Minister of Education, Culture, Sports, Science and Technology Award at the Kanto Region Invention Honors by the Japan Institute of Invention and Innovation for its silicone sheath with superior sliding properties and its application product (invented by Seiichi Kashimura, Masamichi Kishi, Takanobu Watanabe, Kimika Kudo, and Masashi Arai). The award ceremony is scheduled to take place at Hotel Associa Shizuoka on Wednesday, November 29.

1. Invention

Silicone sheath with superior sliding properties and its application product (Patent number: 6699782)

2. Awardees

“Minister of Education, Culture, Sports, Science and Technology Award (MEXT Minister’s Award)”

Seiichi Kashimura,

Materials & Processing Research Dept., Electric Wire & Cable Research Laboratory, Electric Wire & Cable Business Unit, Proterial, Ltd.

Masamichi Kishi,

Materials & Processing Research Dept., Electric Wire & Cable Research Laboratory, Electric Wire & Cable Business Unit, Proterial, Ltd.

Takanobu Watanabe,

Engineering Dept. Ⅰ, Electric Wire & Cable Business Unit, Proterial, Ltd.

Kimika Kudo,

Engineering Dept. Ⅰ, Electric Wire & Cable Business Unit, Proterial, Ltd.

Masashi Arai.

Intellectual Property Dept., R&D Division, Proterial, Ltd.

3. Invention overview

(1) Background

with superior sliding properties

(Silicone cable for medical use SilMED®)

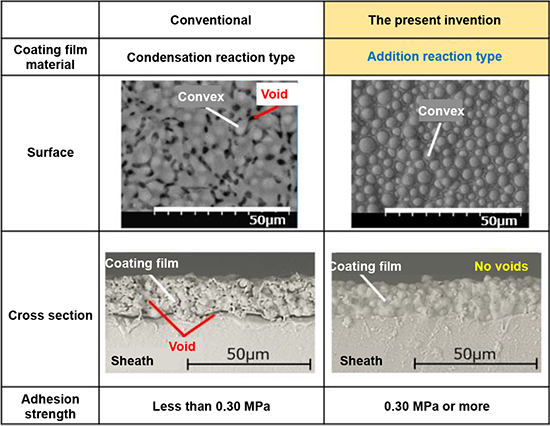

Now, in clinical practice, healthcare professionals are required to sterilize medical devices and connected cables to control infections in hospitals every time they use these devices. Therefore, it is expected that more medical facilities will introduce cables for medical use that have a silicone-based protective outer layer (a sheath) with excellent resistance to chemicals and sterilization processes and excellent biocompatibility. However, silicone-based sheaths have some issues: They become dirty because of the ease of dust adhering to their surface due to stickness, they have poor handleability, and they are not comfortable to patients when they contact the patient’s skin. Therefore, the research team tried to overcome the stickiness peculiar to silicone by forming an uneven coating film on the sheath surface using a condensation reaction material as raw material.*1However, this approach brought about a new issue: A gas was generated on the hardening of the raw material, and the gas caused voids in the coating film. Consequently, the voids reduced the strength of the adhesion between the coating film and the sheath, and decreased the sliding properties when the surface was wiped repeatedly (wipe durability).

(2) Description of the invention

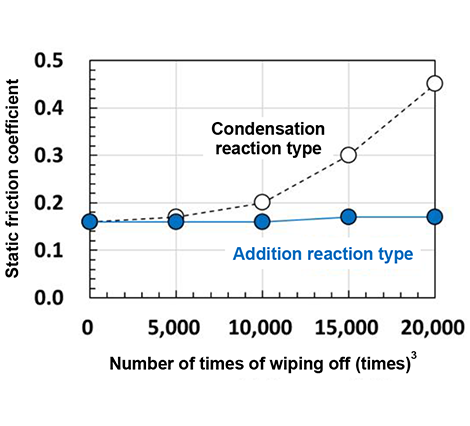

In the present invention, the team focused on the property of the addition-reactive materials*2 that do not easily generate gas. The team formed a void-free silicone rubber coating film by applying a unique surface treatment that suppressed gas generation as the coating film material hardened (see Fig. 1). This approach allowed the team to create a silicone sheath that is highly resistant to chemicals in addition to having superior sliding properties that can prevent the decrease of adhesion strength and wipe durability, which were issues with the previous approach (see the table). The silicone sheath with superior sliding properties can maintain its sliding properties even after 10,000 wipes with a nonwoven fabric impregnated with a disinfectant (see Fig. 2). Additionally, it has been confirmed that the sheath hardly became discolored even when exposed to various types of medical device disinfectants used at hospitals.

More and more medical institutions in Japan and abroad have introduced the product as medical devices such as ultrasonic diagnostic equipment, endoscopes and catheters increasingly require frequent disinfection and sterilization. The development and expansion of this technology is expected to broaden in the future.

and the coating film achieved using the invention

and static friction coefficient

Table. Properties

| Sliding properties | Static friction coefficient: 0.20 or less *6 |

|---|---|

| Wipe durability *3 (nonwoven fabric impregnated with disinfectant *4) | Static friction coefficient: 0.22 or less (after 10,000 wipes) *3 |

| Chemical resistance *5 | Hardly discolored (color difference: ⊿E*ab < 2.5 *6) |

| Biocompatibility | No cytotoxicity *6 (ISO 10993-5) |

(3) Patents

14 patents in total granted in foreign countries (U.S., Europe, China, and South Korea) in addition to 4 patents in Japan

- [Contact for press]

Corporate Communications Department, Proterial

https://www.proterial.com/e/contact/

SilMED is a registered trademark or a trademark of Proterial, Ltd.

- *1A material that forms the main product and a by-product made by separating some of compounds as a result of the combination of multiple compounds. The silicone generates a small amount of gas as a by-product as it hardens. Hardening causes its volume to contract as well.

- *2A material in which multiple compounds combine to form only the main product. The silicone does not generate any by-products and its volume contracts very little when hardening.

- *3The sliding properties of the sheath may deteriorate depending on the type of nonwoven fabric used for wiping, the medical device disinfectant and the method of wiping.

- *4Nonwoven fabric impregnated with ethanol for disinfection, such as Sani-Cloth®HB or Soflight™ (Sani-Cloth is a trademark or registered trademark of PDI, Inc. and Soflight is a trademark or registered trademark of Asahi Kasei Advance Corporation.)

- *5Ethanol for disinfection and many other medical device disinfectants

- *6This represents a test result, not a guaranteed performance standard.