サイアロン製アルミ溶湯部品

サイアロンは、高温構造材料として優れた特性を持ったファインセラミックスです。 当社では、その特性に着目し、アルミニウムの鋳造時に使用される各種の治工具を製作しています。

ロール事業部

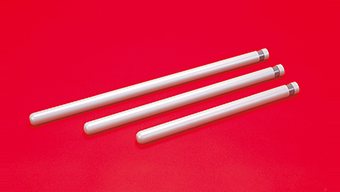

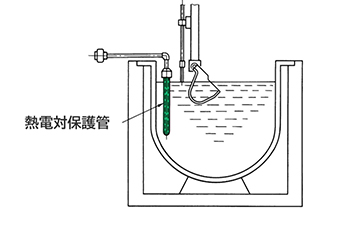

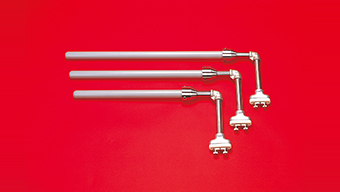

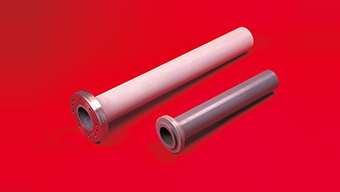

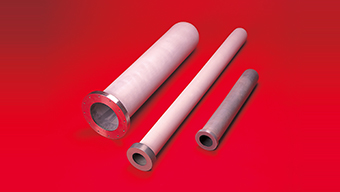

アルミ溶湯測温用熱電対保護管

サイアロン単体および熱電対を組み合わせたL型もしくはS型の組立タイプが選択できます。

標準サイズ(mm)

| 外径φ | 内径φ | 最大長さ |

|---|---|---|

| 11.5 | 6.5 | 500 |

| 15 | 9 | 800 |

| 22 | 14 | 1,100 |

| 28 | 16 | 1,200 |

| 32 | 20 | 1,100 |

| 34 | 20 | 1,900 |

サイアロン保護管(単体)

サイアロン保護管(組立品)

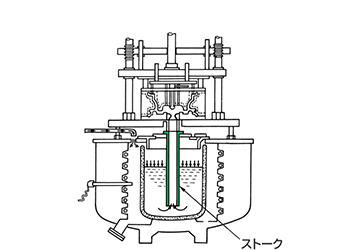

低圧鋳造用ストーク

低圧鋳造機用サイアロン部品として、ストークをラインナップしています。

各種サイズを取り揃えています。

ストーク

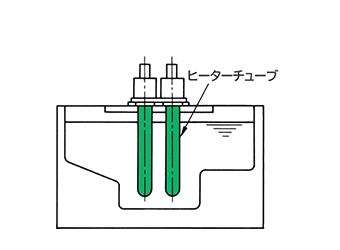

保持炉用浸漬ヒーターチューブ

熱源の電気ヒーター、ガスバーナーに適用できます。

各種サイズを取り揃えています。

ヒーターチューブ

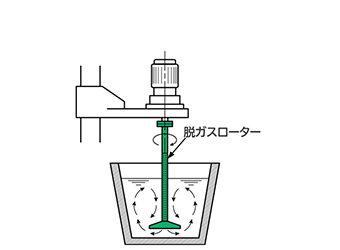

脱ガスローター/バッフル板

アルミ溶湯の脱ガス処理用部品です。標準形状の他、ご相談に応じ製作します。

脱ガスローター/バッフル板

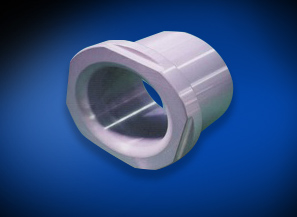

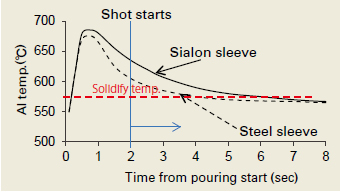

ダイカスト用スリーブ

- 1アルミ鋳造品の品質向上

保温性に優れるため、破断チルの発生を抑制でき品質向上が期待できます。

- 2高い気密性、安定した射出と長寿命(特に700℃以上の高温溶湯で優位)

変形が少なく耐溶損性・耐摩耗耐食性に優れるため、高い気密性、安定した射出と長寿命が期待できます。

- 3省エネ効果

保温性に優れるため、溶湯温度を下げることが可能です。

保温性

ダイカスト用スリーブ(カットモデル)

サイアロンおよびスーパーサイアロン

プロテリアルのサイアロンおよびスーパーサイアロンは、アルミ溶解・鋳造ラインでアルミ溶湯に直接触れる治工具に最適です。

プロテリアルでは従来から蓄積してきた金属材料技術・商品化技術をもとに、耐熱・高強度セラミックス“サイアロン”および“スーパーサイアロン”を開発し、アルミ溶湯部品として実用化しています。

サイアロンおよびスーパーサイアロン製 アルミ溶湯部品の特長

- 1アルミ溶湯に浸食されず、鉄の混入を防ぎます。

- 2アルミ溶湯の付着軽減が期待できます。

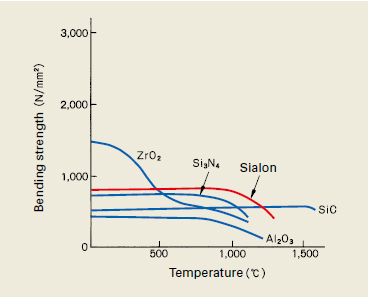

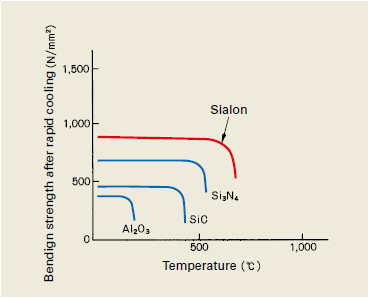

- 3アルミ溶湯温度域で高い強度を維持します。

- 4長寿命が期待できます。

- 52種類の異なった熱伝導率を有しています。

熱伝導率の低いサイアロンは、ストークなどの保温性が要求される部品に適しています。

高熱伝導のスーパーサイアロンは、ヒーターチューブなどの高い熱伝導を必要とする部品に適しています。

特性値

| 材質 | 密度 (g/cm3) |

4点曲げ強さ (MPa) |

ヤング率 (GPa) |

耐熱衝撃性 (ΔT°C) |

熱膨張係数 (×10-6/°C) [20~800°C] |

熱伝導率 (W/m・K) |

耐熱温度 (°C) |

|---|---|---|---|---|---|---|---|

| サイアロン | 3.2 | 750~950 | 290 | 710 | 3.0 | 17 | 1,250 |

| スーパーサイアロン | 3.2 | 800~1050 | 300 | 750~1000 | 3.0 | 65 | 1,250 |

高温強度

耐熱衝撃性

この資料に記載の材料特性、データ等は参考値です。製品の寸法、形状、表面状態、測定箇所、測定方法によって変動する場合がありますので、全ての製品についての保証値ではありません。

ロール事業部

その他の製品・ソリューションを探す

ABOUT US

持続可能な社会を支える高機能材料会社

売上収益

7,686億円

全従業員数

18,877人